What do you do at Realize?

Client Success Manager. I manage a core group of clients and projects that flow through the office. Make sure they are accurate and satisfied. Follow up on new prospects and clients.

What attributes are needed for your position?

Good attitude and work well with a group, you need to perform at a high level. Problem solver and communicate well.

How did you get here?

I got my design degree from Purdue…worked on industrial design, product development , 3D CAD materials and processes and Rapid Prototyping. Things have changed alot in past 12 years…the market is larger and the technology has taken off…the tech in materials have improved so much.

Name some of your favorite things in the world.

Concerts, working out….weights and cardio..sports…Purdue and Colts…not IU…skiing too.

How does Realize do things differently than the competition?

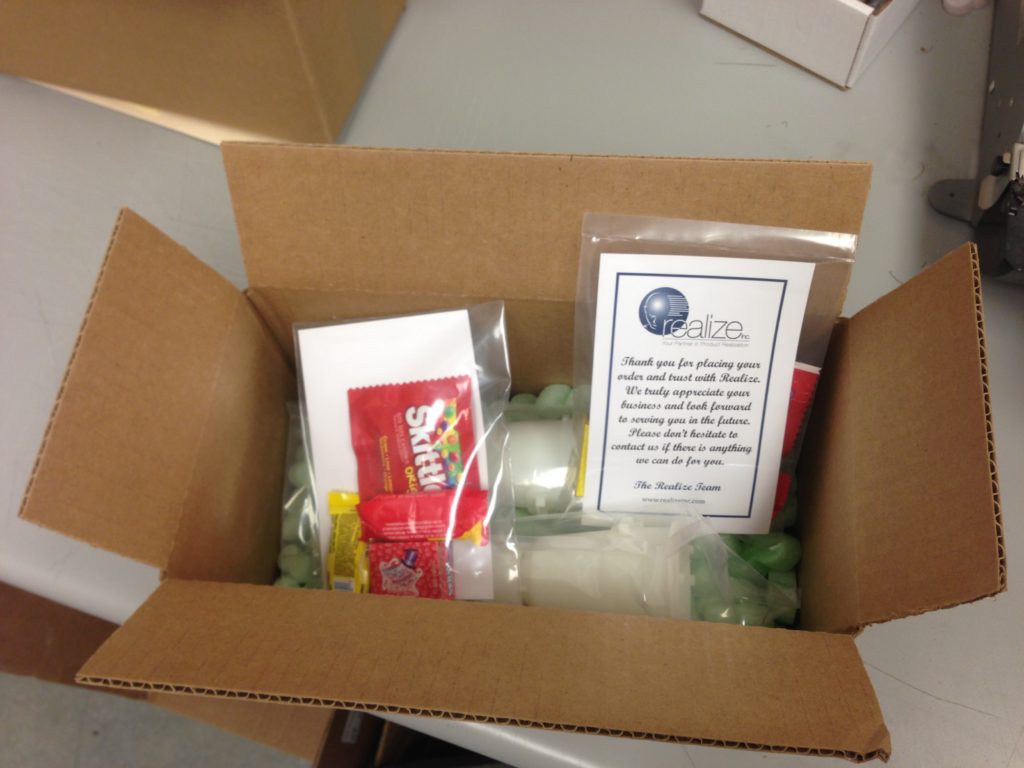

I think the people and personalities are strong and important. We focus on giving our full attention to customers. Faster service and personal touch go a long way. We strive to stay upfront and focus on getting as much information ahead of time. This makes the entire process easier, there is less email and it streamlines communication and the process for a higher degree of success for our clients projects.

Favorite meal?

Steak…bone in rib-eye…Ruth Chris is my favorite…no butter…ruins the taste and sweet potato casserole with a nice big glass Fat Tire…and for dessert…Creme Brûlée!

What music are you listening to right now?

I listen to rock and rap. But Dave Matthews Band is my favorite and the Black Keys…Flo Rida is great for workouts.

You can take two movies with you to space…which do you bring?

Princess Bride and Wedding Crashers.

One word that describes you?

Focused.

What elements of the Rapid Prototyping world fascinates you most?

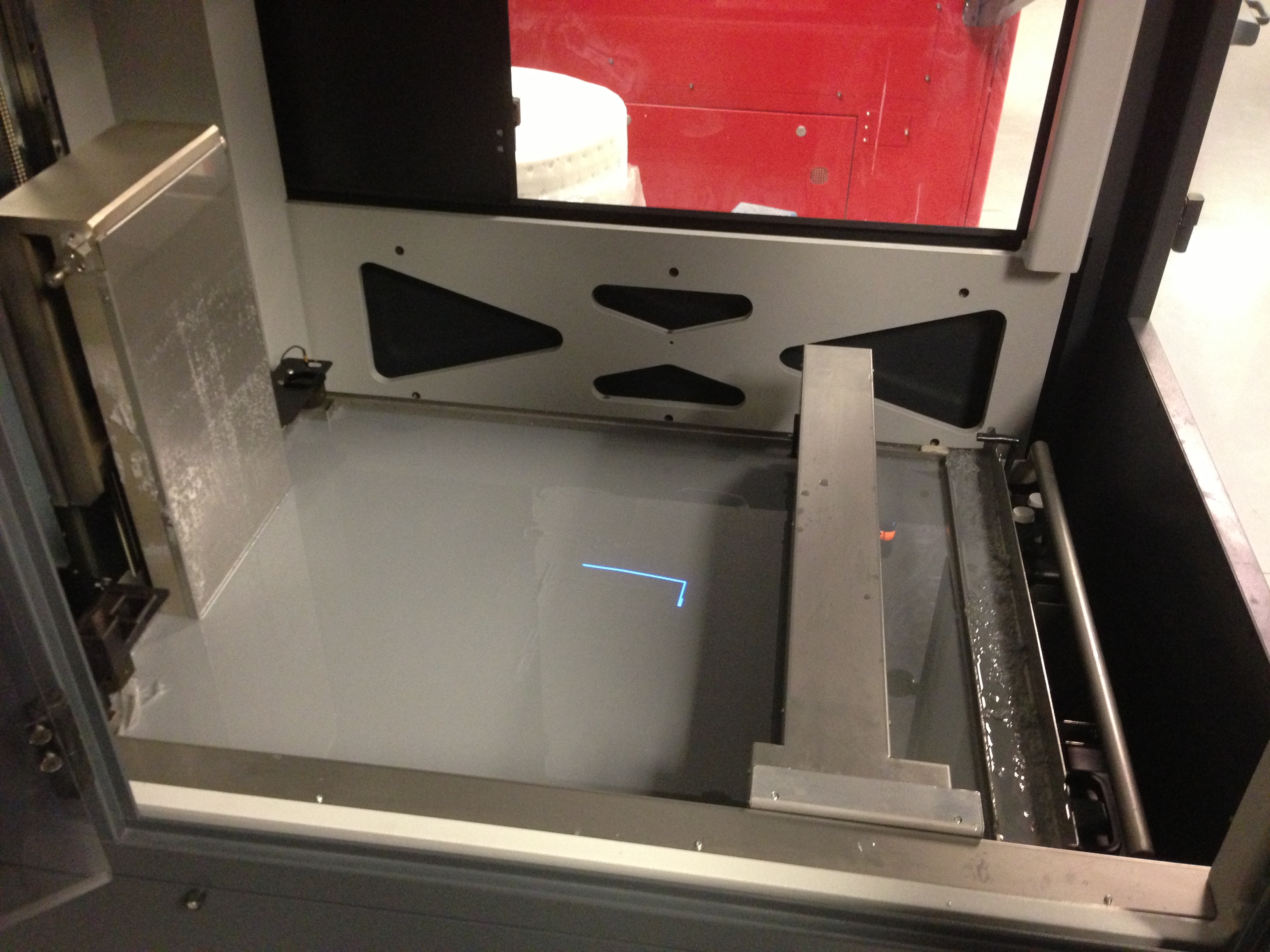

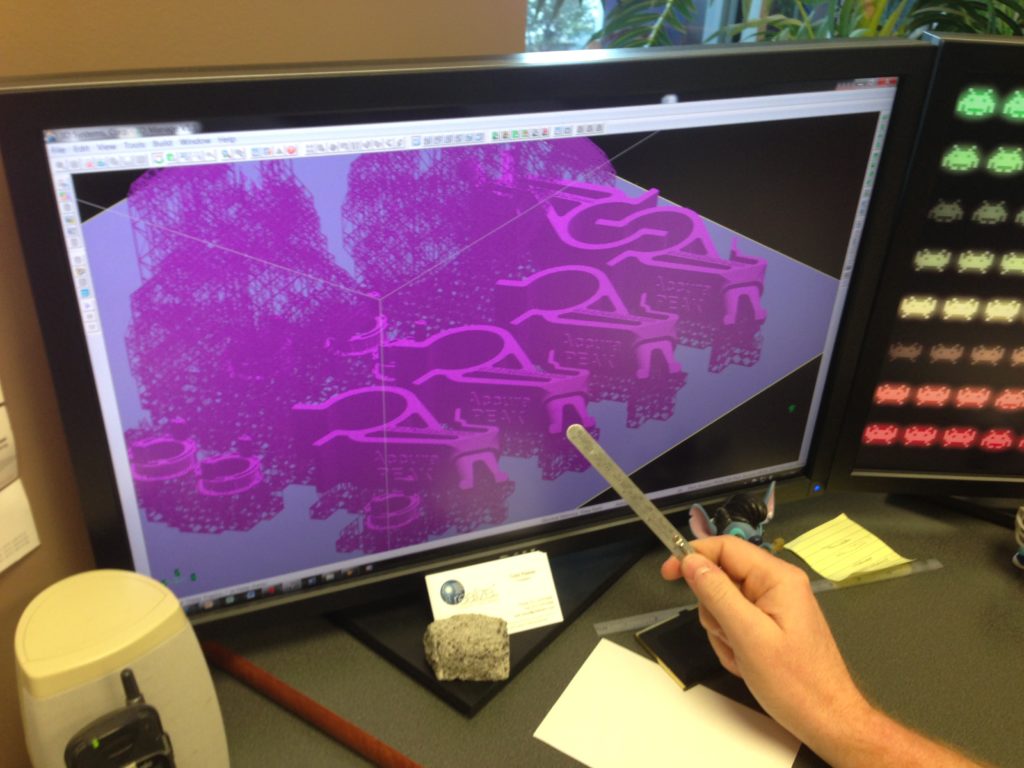

The Idea of generating a real world model from 3D data, translating and converting that CAD file to something that you can feel and touch. People are amazed at what is possible…things had to be man made in the past and now we have technology that creates using materials and machines.

Any particular jobs at Realize that stand out to you?

Some of the jobs that we can’t talk about are the most exciting, and that is tough but secret projects are cool.

[lenslider id=”feb482efbb”]

3D Printing/Rapid Prototyping/Additive MFG

3D Printing/Rapid Prototyping/Additive MFG