Realize Featured Project: Fogo Ultimate Adventure Gadget

It’s always exciting to work on new projects that have the potential for coolness like the new Fogo Ultimate Adventure Tool Gadget! Many times we are working on projects that get the entire Realize, Inc. team buzzing with enthusiasm, but we’re not always able to talk about everything we do, some projects are TOP SECRET. So it’s with great pleasure we share some information about this cool little gadget known as Fogo. We talked with Co-Founder Dustin Bouch about his new product.

Realize: Tell us about your product.

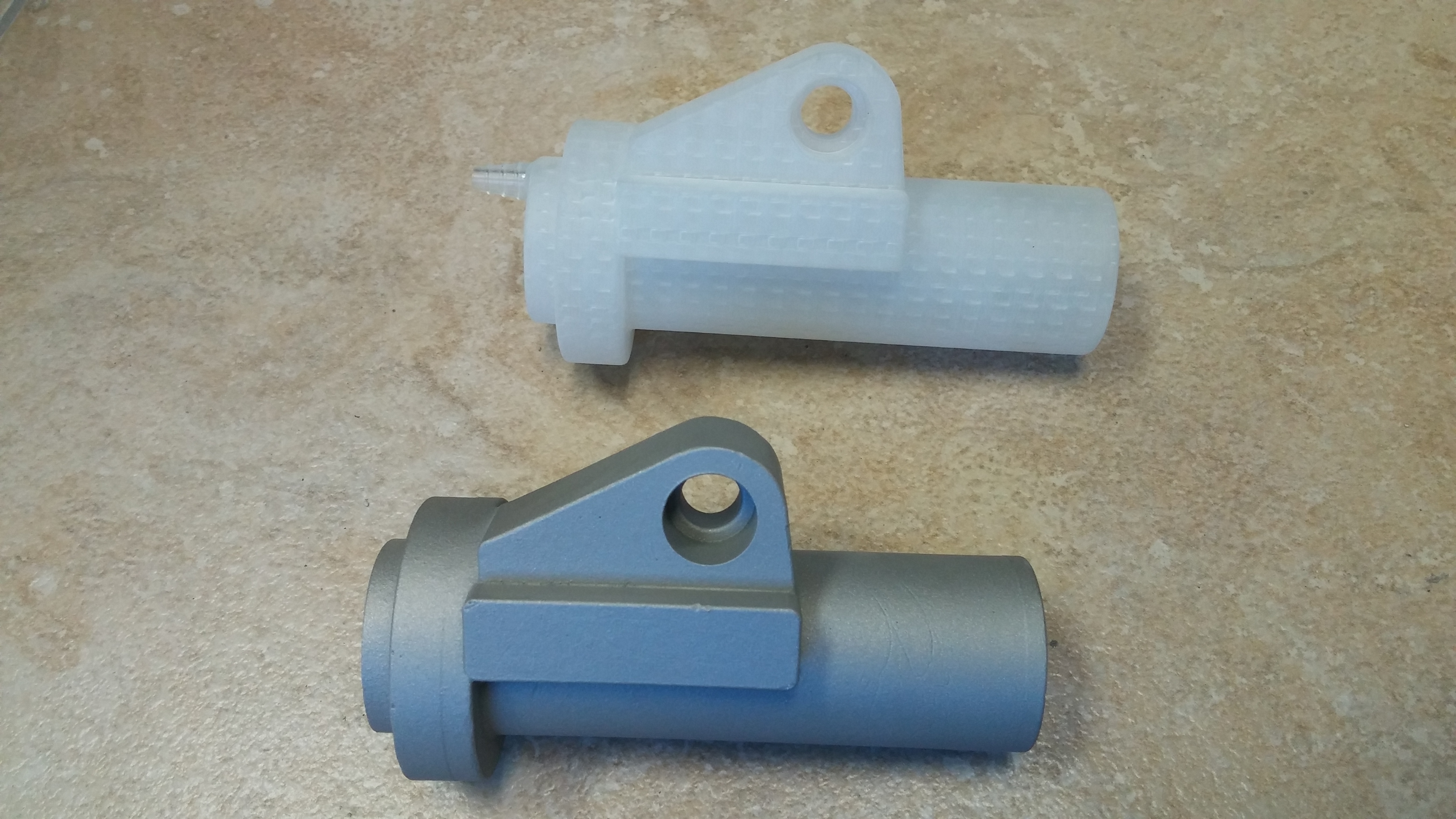

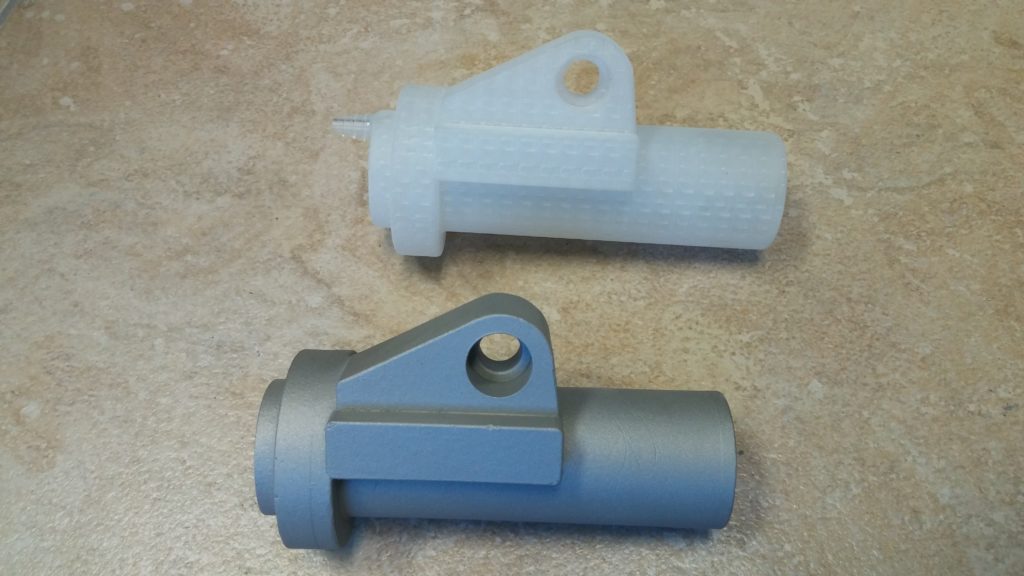

Dustin: The Fogo is an outdoor device that combines a GPS receiver, powerful LED flashlight, digital walkie-talkie, and USB back up battery. It helps keep outdoor enthusiasts safe and lightens their load.

How did you use Realize and 3D Printing to help with you project?

We utilized Realize to prototype all the plastic components during the development phase. This included a couple snap fit parts and a light guide that Realize did a great job of polishing and clear coating for us to make it 100% functional. Realize gave us great parts with a fast turnaround time.

How do you think you will use additive manufacturing in the future and are there any new directions or capabilities you would like to see in the industry?

We will continue to use 3D printing to support our development efforts for the foreseeable future. We look forward to seeing stronger materials.

What were the biggest challenges with creating the Fogo Adventure Gadget?

Our biggest challenge was packaging a lot of parts and electronics into a small envelope. We also have some tough constraints for durability and waterproofing that required a lot of effort in analysis, iterative design and testing.

With such a cool product coming out is there a follow up idea you have ready to go?

The Fogo has an interchangeable component capability that we call the SmartCap. It allows the user to swap SmartCaps on and off the device to add hardware capability and configure the device for different activities. For example, the walkie-talkie is actually part of a SmartCap, so our customers can either buy the Fogo now with the walkie-talkie functionality or buy it and plug it in later down the road. We have immediate plans to make additional SmartCaps such as a Satellite Modem SmartCap, Avalanche Beacon SmartCap and Laser Range Finder SmartCap.

What is something that you personally would like to have 3D Printed?

I would love to 3D print a replica of my dog Lou! He is a 20 pound terrier poodle mix and it would be amazing to have a little statue of him in my house to torment him with!

Where can people get more info on the Fogo?

We are running a Kickstarter campaign so we can raise money to get the Fogo out on the trail. Please check out our Kickstarter page

3D Printing/Rapid Prototyping/Additive MFG

3D Printing/Rapid Prototyping/Additive MFG