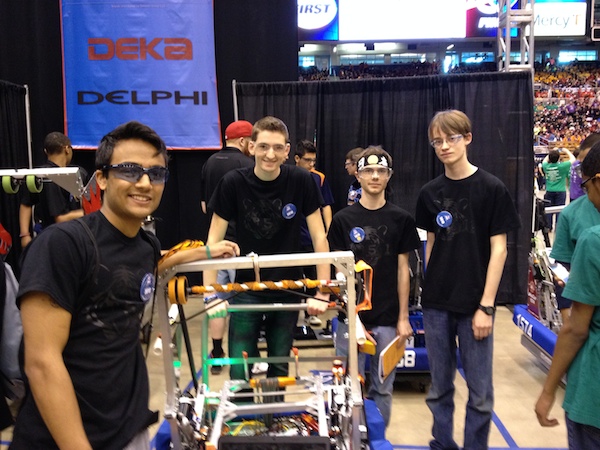

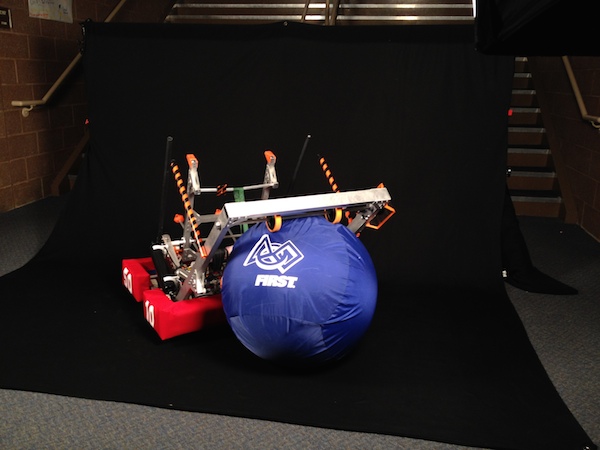

Realize, Inc. is proud to support local science and technology students in the Indianapolis area. Recently we sponsored the Hamilton Southeastern High School Robotics Team. We talked with HSE Physics/Pre-Engineering Teacher Jeff Wilkins about the program.

Tell me about the HSE Robotics Team, What does your team do?

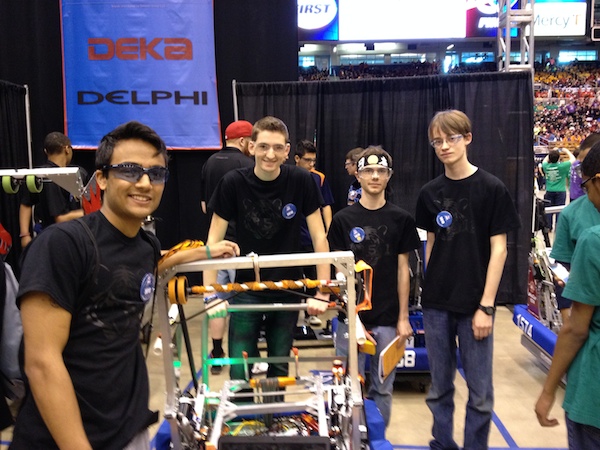

HSE Robotics, aka Royal Robotics, started back in 2005. That year, my Principles of Engineering (POE) classes participated in BEST Robotics (www.bestinc.org) and the Digital Electronics (DE) class participated in Botball (www.botball.org). The robotics club at HSE now participates in the VEX Robotics Competition (www.vexrobotics.com) and has been competing since 2010. BEST Robotics requires students to make a robot out of common materials from scratch. Plywood, PVC and some sheet metal are the main materials used to create these robots. My Engineering Design and Development (EDD) class still participates in this competition to this day. Botball is a completely autonomous robotics competition that requires the team to build a robot out of a lego platform and an iCreate (from the company that brought us the Roomba, iRobot). Students have 8 weeks to design, build and program a robot to complete the task for the year. VEX Robotics is where our after school Robotics Club will compete. This competition uses materials that are used in the PLTW program and the parts and pieces are premade, so designing and assembling a robot is very quick and easy.

Why is this team important for students and the school?

We have over 50 students participating in Robotics Club this year, as well as, 22 students in EDD that are participating in the BEST Robotics Competition.

How did the Realize Sponsorship help your team?

Your generous donation allowed us to purchase a GCC Laserpro Spirit GX laser cutter which is used for fundraisers for robotics club and to cut the main chassis of our robots for the BEST Competition.

What do you love about Robotics?

Robotics is sports for geeks. It has all of the excitement, hard work, and practice of athletic sports and allows students to excel on a different playfield.

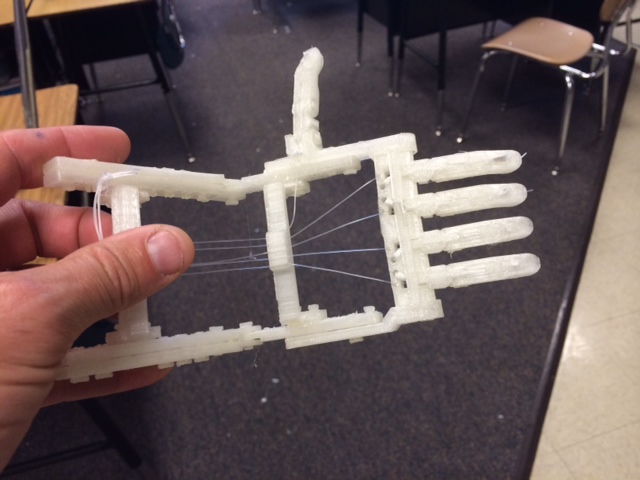

How can you see Robotics and 3D Printing working together in the future?

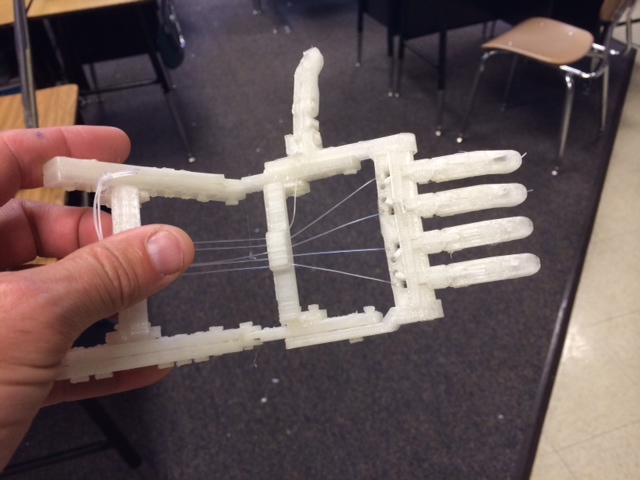

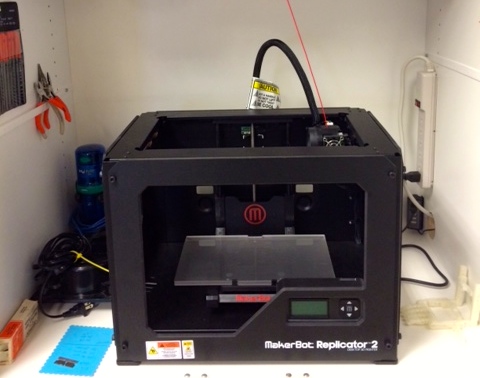

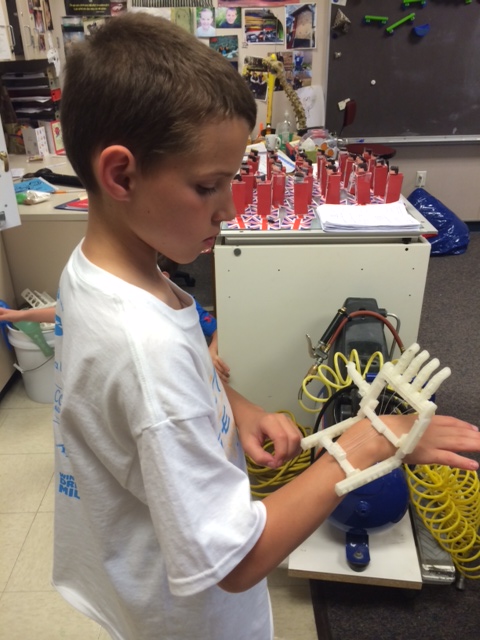

Yes, we will be using our 3D printer to create parts and pieces for an R2D2 that we will be building next semester. It allows someone to design the robot in a 3D modeling software and get a prototype very quickly without expensive and time consuming machining.

What do you think students need more information on regarding the additive manufacturing industry?

All of the different types that are available. Most just think of FDM because that is what we have at HSE, but there are so many other options out there.

If you could 3D Print anything, what would that be?

Well, since I own one, I can print about anything I want, but 3D printing a house out of concrete would be really cool. My favorite item to 3D print so far were a bunch of digital sculpts that the Tech Art Club at Fall Creek Intermediate students designed. They were very excited to get a physical model of what they had designed on their iPad’s using 123D Creature App.

*If you have any questions or are interested in sponsoring you can contact Jeff. [email protected] 317-594-4190 ext. 11521.

3D Printing/Rapid Prototyping & Manufacturing

3D Printing/Rapid Prototyping & Manufacturing