One thing that’s exciting about visiting Realize is the tour of our facility.

Rapid Prototyping not only sounds like something cool, it’s an interesting process.

Watching the team take on new projects is something special…so I snuck in one day and bothered them to give you this report.

I give you…the Realize process…or at the very least my version of it:) Enjoy – Ray

Step 1 – contact

Our friendly client success managers will answer and ask questions to find out the scope of your project to find the best solutions for you, in between group sing a longs and youtube viewing parties of course.

Step 2 – Quoting

We will then work on getting your quote. It’s a formula driven estimate that combines equipment and a human element. And other technical stuff too I’m sure…but could not find pictures of that.

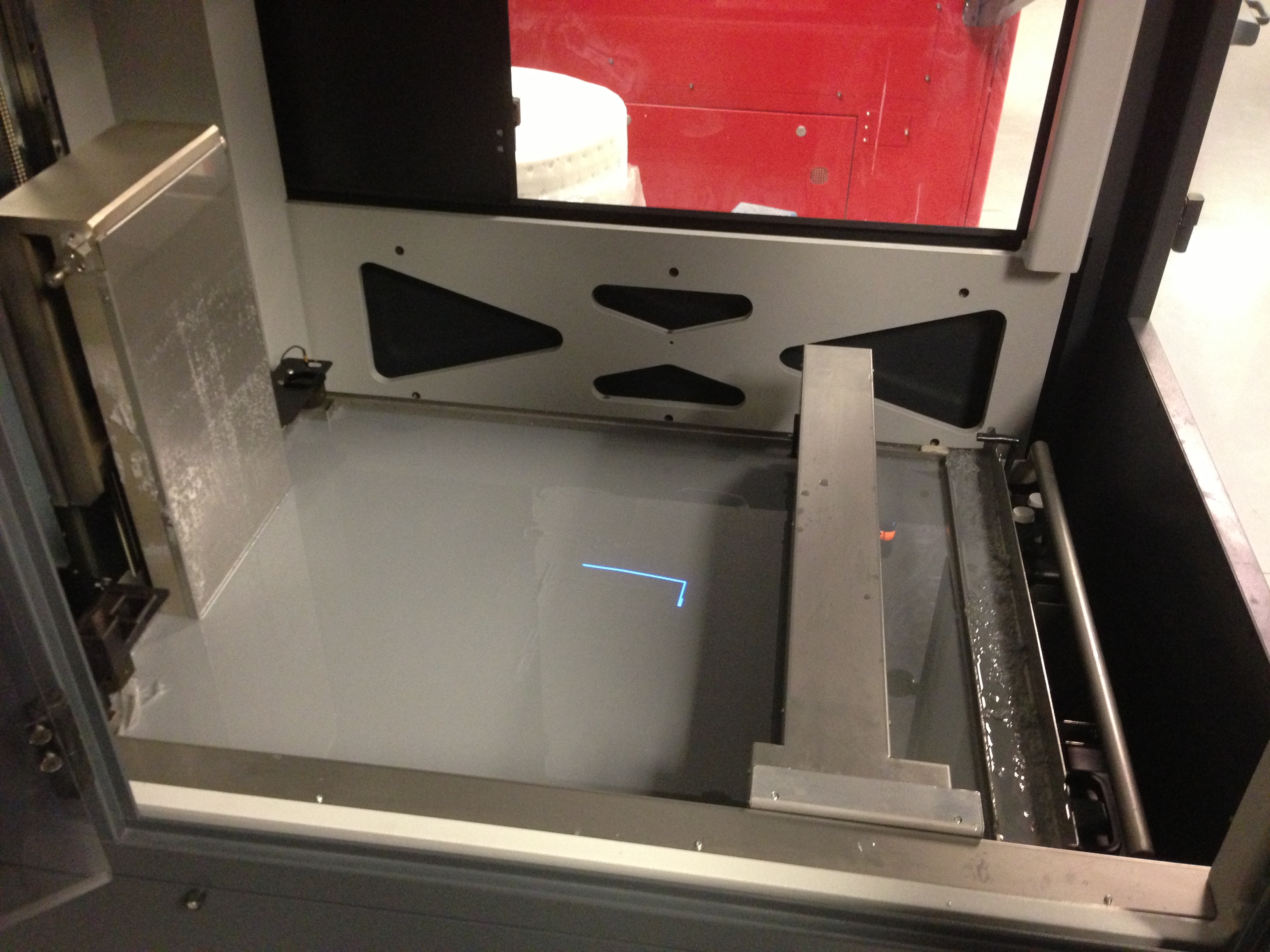

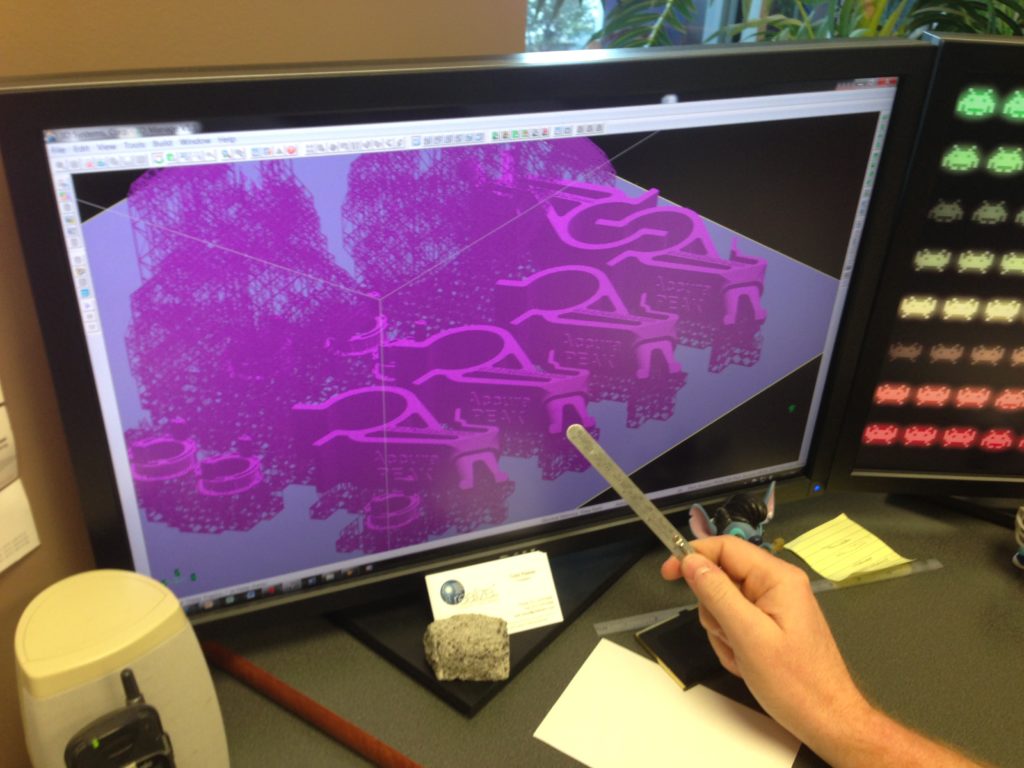

Step 3- Stereolithography process

Once we agree on a direction for your project then we execute the stereolithography process. This is science and art driven. Our expertise will provide the best part in the end. I misspelled Stereolithography several times in this post btw.

Step 4 – The Machines!

Our machines not only are state of the art, we also have named each of them after supermodels. It’s where science and fun come together in a truly magical way.

Step 5 – Clean up

The clean up process involves several steps. Removing Support, liquid resin stripped away and a curing process. There are many secrets we can’t reveal that occur during this phase…I could tell you but then I would have to…well you know.

[lenslider id=”d2ed814d73″]

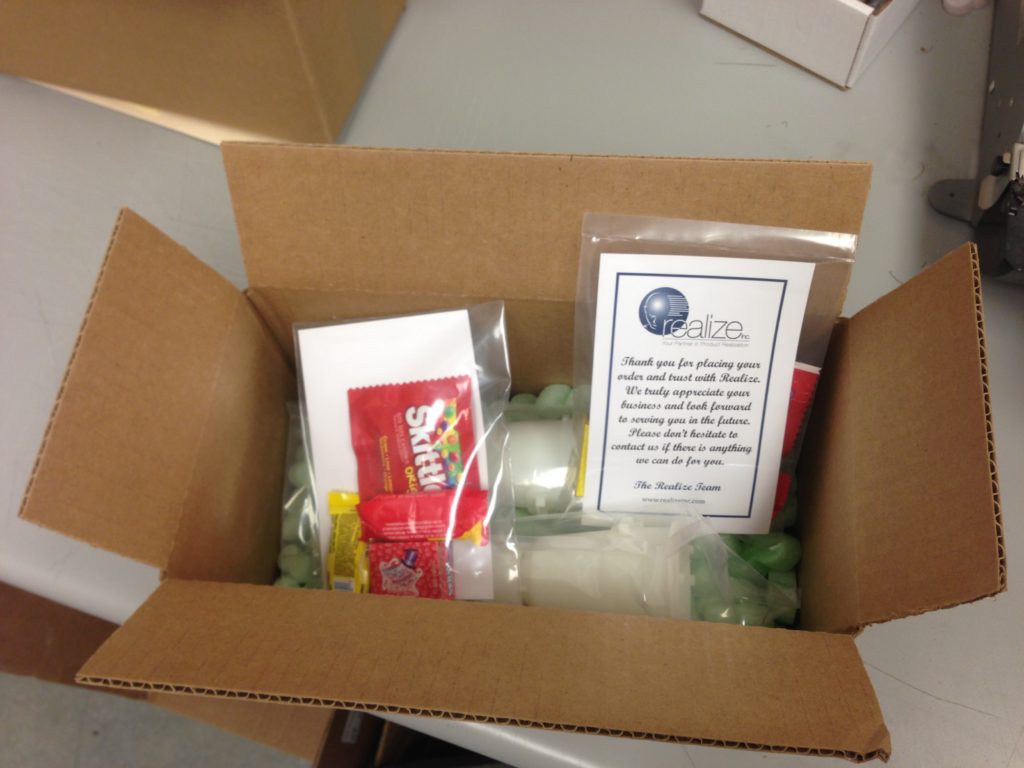

Step 6-Delivery

You will get the finest prototype part that can be created combining technology and the human element…and some candy too!

3D Printing/Rapid Prototyping/Additive MFG

3D Printing/Rapid Prototyping/Additive MFG