Realize is always seeking out conversations with experts in the additive manufacturing industry. For this Q&A we interviewed Buddy Byrum, 3D Systems’ vice president of product and channel management, personal and professional 3D printers.

What do you feel is the most groundbreaking piece of equipment you’ve introduced? Why?

I think there are a couple, to be honest. We released the ProX 950 at EuroMold 2013, and it’s the type of machine that can vastly increase the capabilities of manufacturers (aerospace, medical devices, automotive, turbine production, casting applications) and service bureaus because of three factors: it’s huge, it’s highly accurate and it’s fast. With PolyRay™ we’re talking print speeds up to ten times faster than other 3D printers. And it can print models as large as a full engine block, so users can spend less time on assembly, produce huge casting patterns faster, produce test models faster and get end products into production and ultimately to the customer.

I’d also say the ProJet 4500 is a big development in 3D printing also because it’s the industry’s only photorealistic, full-color 3D printer that creates durable plastic parts. The 4500 gives consumer products designers, healthcare companies, toy makers, architects, etc. the ability to make gorgeous, true-to-life prototypes that stand up to the real world. They can even make end-use parts quickly, allow manufacturers to customize them and enable whole new product lines.

Of the technologies you offer, which is currently receiving the most attention in-house for future development and why?

We cannot really comment about specific developments, but we are always working on new materials for our technologies to expand their use. Today we 3D print with over 100 different materials ranging from food ingredients to waxes to various plastics and even metals so we continue to grow the range of functional materials to bring the benefits of 3D printing to more and more applications.

What stands out as the most outstanding use of your equipment?

That’s a tough question. The beauty of 3D printing is that you can produce virtually anything, regardless of geometry, and do it faster and often more accurately.

But I think the strides that we allow traditional manufacturers to make are really exciting. The fact that we can put one of our machines into a traditional manufacturing outfit and give them a way to optimize a traditional manufacturing workflow or a product development method with 3D printing is amazing. And it shows the versatility of 3D printing, that it can constitute the entire manufacturing process or it can integrate into an existing process. Whether it’s making casting patterns faster and more accurately, producing working prototypes for fit and function in a day, or being able to recognize design flaws early.

We recently had a service provider who helped a natural gas equipment manufacturer create test parts of a regulator housing. With 3D printing, using one of our ProJet 3500 printers, they were able to produce patterns and eventually aluminum test parts in only 9 days. Prior to enlisting this service provider, the gas equipment manufacturer couldn’t even create accurate test parts (using CNC machining) that would fit on their assembly! The geometry was just too complicated. But with 3D printing they not only got test parts that fit but they got them fast.

What are your thoughts on 3D food and clothing and all the headline-grabbing posts about our Industry that are daily tech stories online?

As I alluded to earlier, this technology may never find a limit. While we’re still in the early stages of 3D printing food and clothing, there’s no reason to think that these applications couldn’t become mainstream or even the norm down the line. Clothing designers have really embraced 3D printing on fashion runways because it offers a way for them to create some complicated forms and novel new textiles.

Are there any new applications for Rapid Prototyping you feel will emerge over the next few years?

With our introduction of the first full-color plastic 3D printer (ProJet 4500), real functional prototypes can also have photorealistic color. With this capability prototypes can be both functional and provide the full customer experience feedback as they can have realistic looking test prototypes directly out of the printer.

What are the strangest requests or questions you get about your machines?

The strangest questions often come from people who do not understand digital files or 3D designs. We are asked from time to time if we can print directly from a 2D drawing or photograph. This is not as strange as it used to be though because we do have the capability to create our 3DMe figurines starting with just two photos.

If you could make a prototype of anything in one of your machines with no care given to time or cost, what item would you like created?

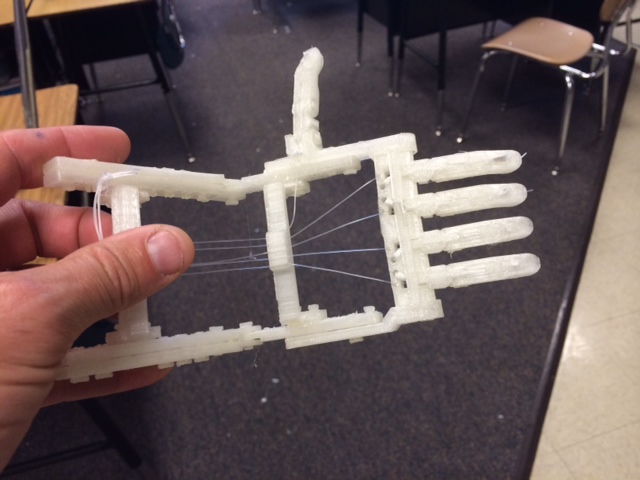

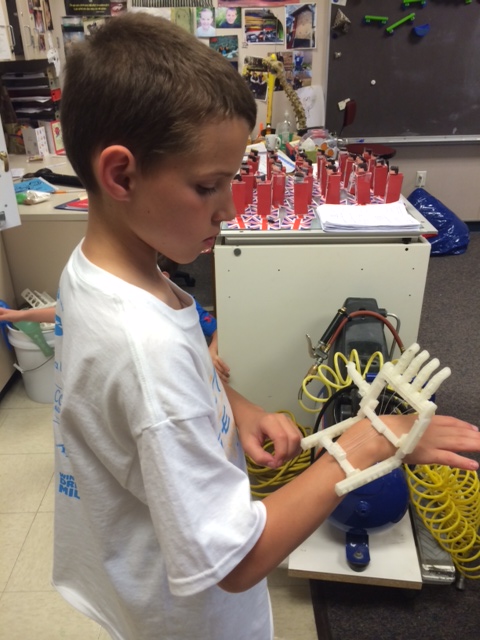

I would have to say life-saving, or quality-of-life improving items such as new medical devices or replacement body parts. We already have customers doing these kinds of applications and it is rewarding to know we are enabling a growing list of such applications that have the power to change the world and have meaningful impacts on people’s lives.

Why has 3D Printing become the buzzword for the entire industry and do you think that is a good or bad thing?

I think it’s a good thing, and it’s a term that we have encouraged because it’s the best descriptor for what we do and it doesn’t make the general public believe that it’s just for manufacturers. Regardless of what it’s called, the fact that it is a buzzword at all is a great thing. If 3D printing is in the public consciousness, that’s a win for everyone: for 3D printer manufacturers, professional users, consumers, makers, manufacturers, artists, museums … everyone.

What trends should AM business owners be looking to follow over the next century in your opinion?

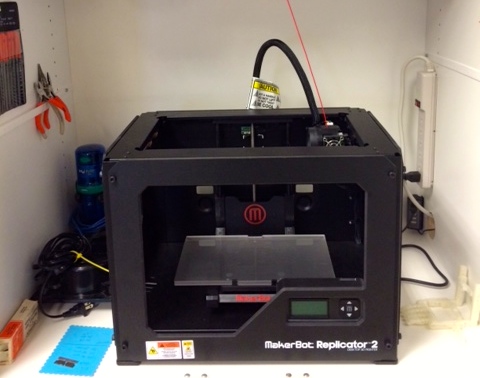

Two important trends stand out in my view. First is the democratization of 3D printing that opens new entrepreneurial doors for people to start new businesses, design new inventions and manufacture their dreams within their own means and circumstances. 3D printing breaks down geographic, economic and infrastructure barriers and provides ordinary people the opportunity to create without limits. Second is use of AM in real manufacturing applications, either directly or indirectly. Designers are learning to create new levels of product performance impossible within traditional manufacturing limitations and are now designing end products to take advantage of the limitless geometry capabilities afforded by 3D printing.

Where do you think 3D Printing will be 50 years from now? (This is just a fun guess, futuristic question)

I hope my ability to still be 3D printing in 50 years will be helped by the advances in healthcare that 3D printing offers! I could imagine colonization of other planets where 3D printing allows people to make whatever is needed, when needed. Back on earth the word “inventory” may no longer be needed!

3D Systems is a leading provider of 3D content-to-print solutions including 3D printers, print materials and cloud sourced on-demand custom parts for professionals and consumers alike with materials including plastics, metals, ceramics and edibles. The company also provides integrated software and hardware tools including scan to CAD and inspection. Its expertly integrated solutions replace and complement traditional methods and reduce the time and cost of designing new products by printing real parts directly from digital input. These solutions are used to rapidly design, create, communicate, prototype or produce real parts, empowering customers to manufacture the future.

3D Printing/Rapid Prototyping & Manufacturing

3D Printing/Rapid Prototyping & Manufacturing