Please

APPLY HERE if you are interested and qualified for this position. Thank you.

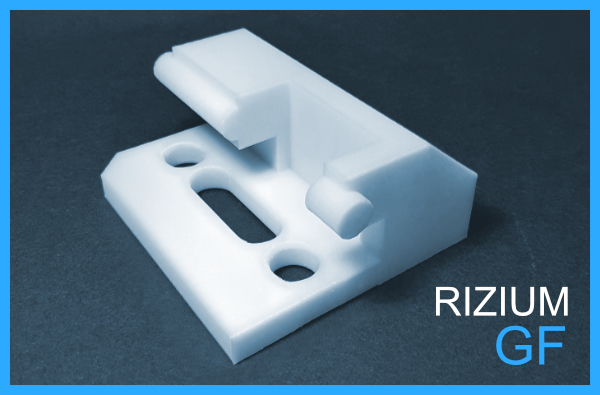

Prototype Finishing Technician Realize Inc. – Noblesville, IN 46060

$16 – $19 an hour

Details: Noblesville product development company specializing in the manufacture of prototype models is searching for an experienced finisher / model maker for its 3rd SHIFT operations. This is a full-time position with benefits. Position will train w/First Shift and eventually become permanent 3rd Shift (Sunday through Thursday) after approximately 90 days with a weekend “on call” rotation. The Finishing Tech will work primarily in the stereolithography (SLA) machine lab and finishing department. Work consists of finishing highly detailed SLA models which includes detailed intricate hand-sanding of parts, support removal, parts washing and bead blasting. In addition, the position will be responsible for machine turnover and maintenance.

Qualifications: Qualified candidates will have experience with 3D printing and SLA model finishing techniques and/or model making. Finely detailed painting experience is a plus. Work will be performed on 3D Systems Viper machines, 5000’s, and iPro 8000 and 9000 systems. Must be dependable, trustworthy, and be able to work with minimal supervision. Must be able to communicate effectively with others and work well in a cross functional team environment. Must have a passion for excellence in a fast paced environment. Some heavy lifting (up to 50 lbs.) will be required. Valid IN driver’s license required.

Specific day-to-day responsibilities include :

Removing completed platforms of parts from machines and perform post-processing, support removal, and curing

Reset machines and prepare for next platform build

Perform basic model finishing with appropriate techniques (hand-sanding, bead blasting, polishing, painting)

Perform maintenance on SLA machines as required

Perform liquid resin vat changes in SLA machines

Diagnose malfunctions and communicate directly with supervisors if issues arise

Perform daily cleaning and maintenance in the finishing department as required

The handling of large boxes and heavy lifting (up to 40-50lbs) may be required

Assist in other areas as needed and perform other duties as assigned

All of these tasks must be performed quickly enough to meet Realize’s production schedule

Expected Pay Range: $16-19/hr.

Job Type: Full-time

Job Location:

Noblesville, IN

Required education:

High school or equivalent

Required experience:

Prototype Finishing, Model Making, 3D Printing Machine Operations: 1 year

Required license or certification:

Driver’s License

3D Printing/Rapid Prototyping & Manufacturing

3D Printing/Rapid Prototyping & Manufacturing

Rizium Carbon

Rizium Carbon