What is your role at Realize?

Master Painter and detail specialist.

I work on projects that require a little more attention and detail. Lots of painting and clear coat techniques. It takes some thought and creativity to bring some of these prototypes to life.

Which item you have worked on was the most fascinating?

The naughty librarian of course….a client asked for a desktop model of one of his products…it’s 25 pieces and hardest part of creating it was blending skin tones and making the stockings look real.

What do you think are the attributes required to do your job?

Multitasking and staying efficient are a must. You need to constantly think outside of the box.

Name some of your favorite things in the world.

Good dry English humor…if you can’t have fun you might as well be dead…so I try to have fun. I like to paint miniatures, play war games, war hammer table top war game is my current favorite. I like to read and consider myself a military history junkie. My favorite war is WWII.

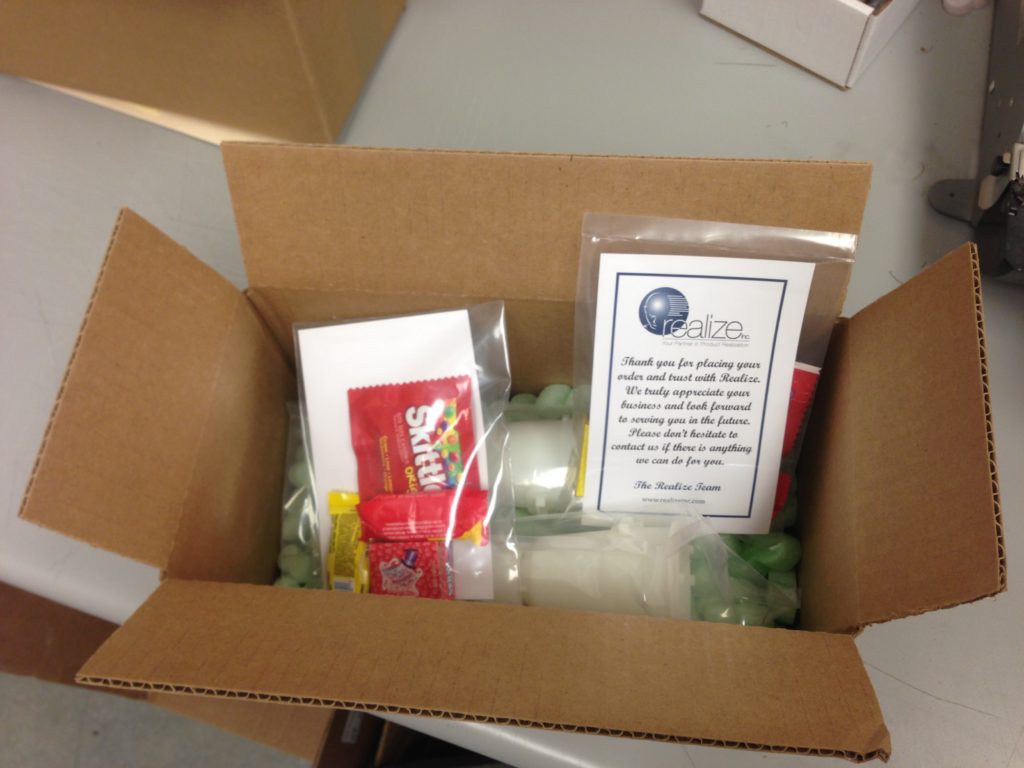

How does Realize do things differently than the competition?

Realize allows for independent thought and creativity. This allows employees to flourish and ultimately that benefits the customer and makes a huge difference.

Favorite meal?

Taco bar at any restaurant….I love tacos.

What music are you listening to right now?

Rush…it’s all Rush all the time…favorite song is Time Stand Still.

You can take two movies with you on a trip out to space…which do you bring?

Star Wars original and Lord of the Rings.

One word that describes you?

Fun.

One thing you would like to Rapid Prototype for yourself?

A Sherman Tank….its a big M4 WWII tank.

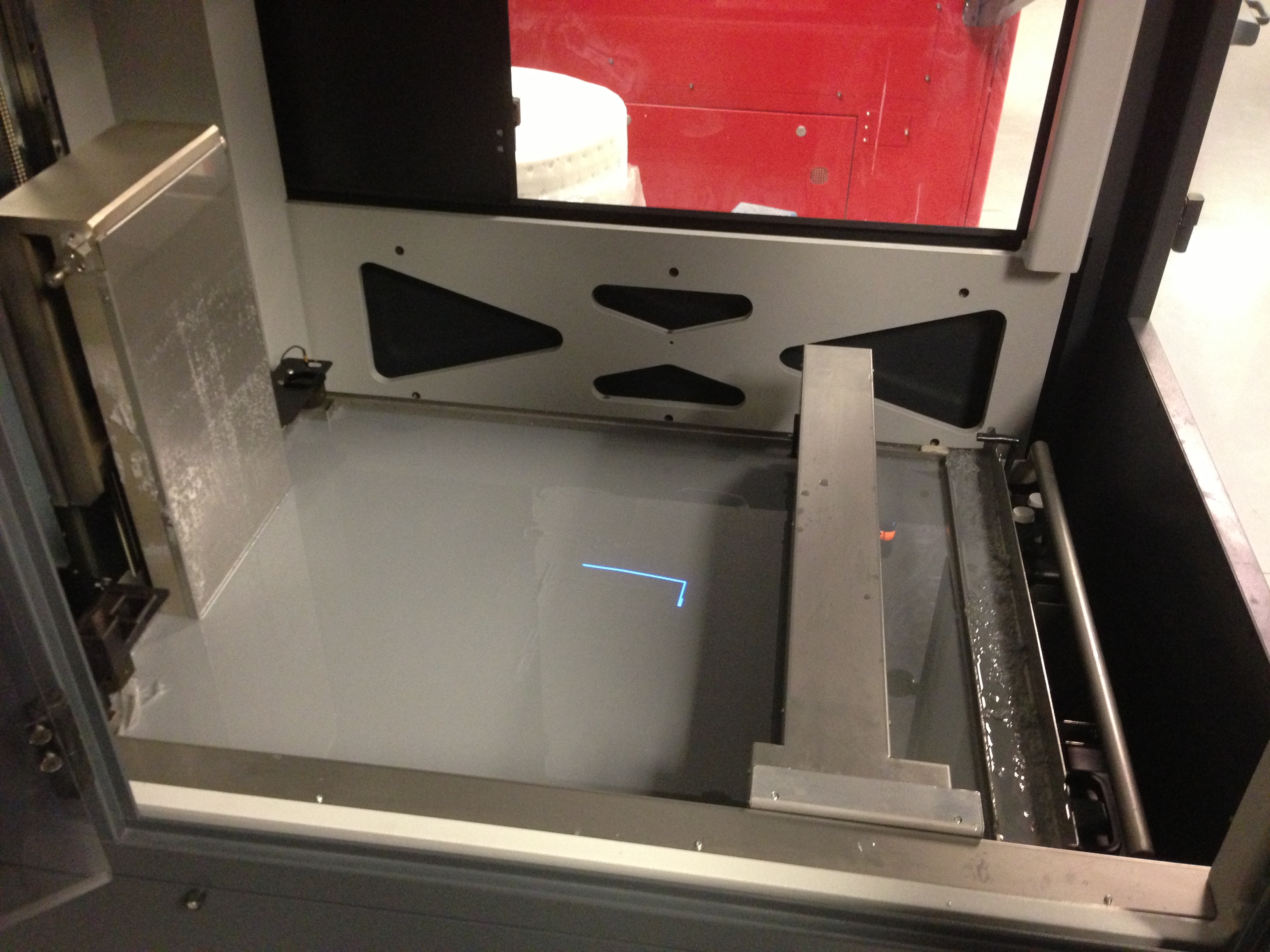

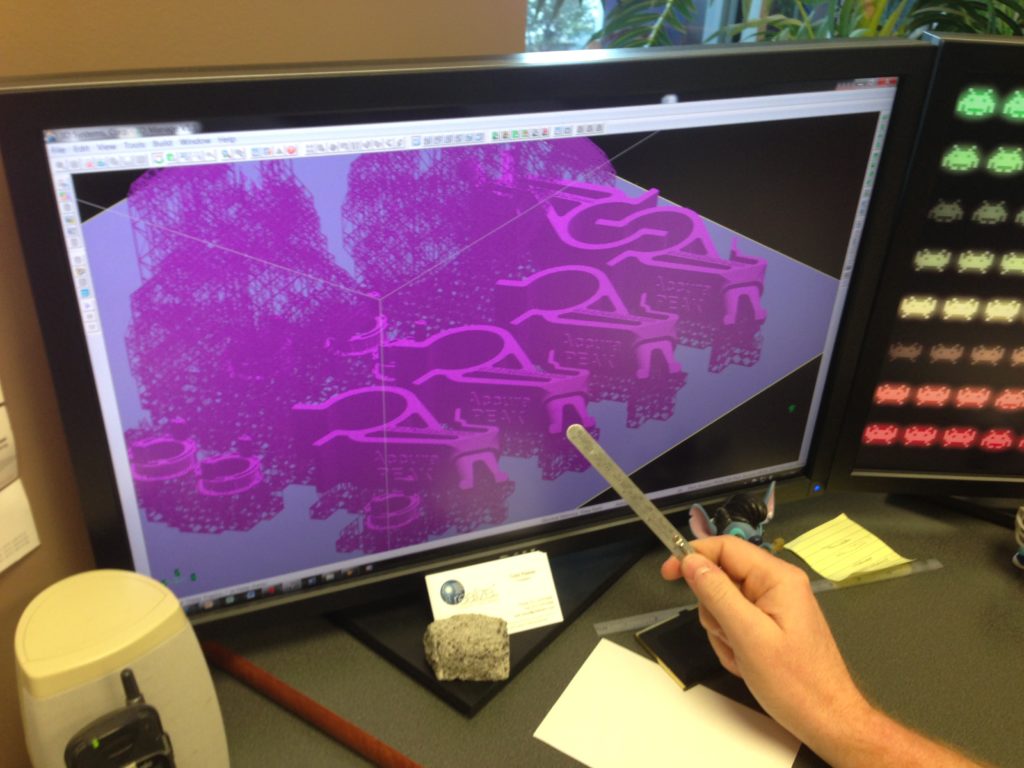

3D Printing/Rapid Prototyping/Additive MFG

3D Printing/Rapid Prototyping/Additive MFG