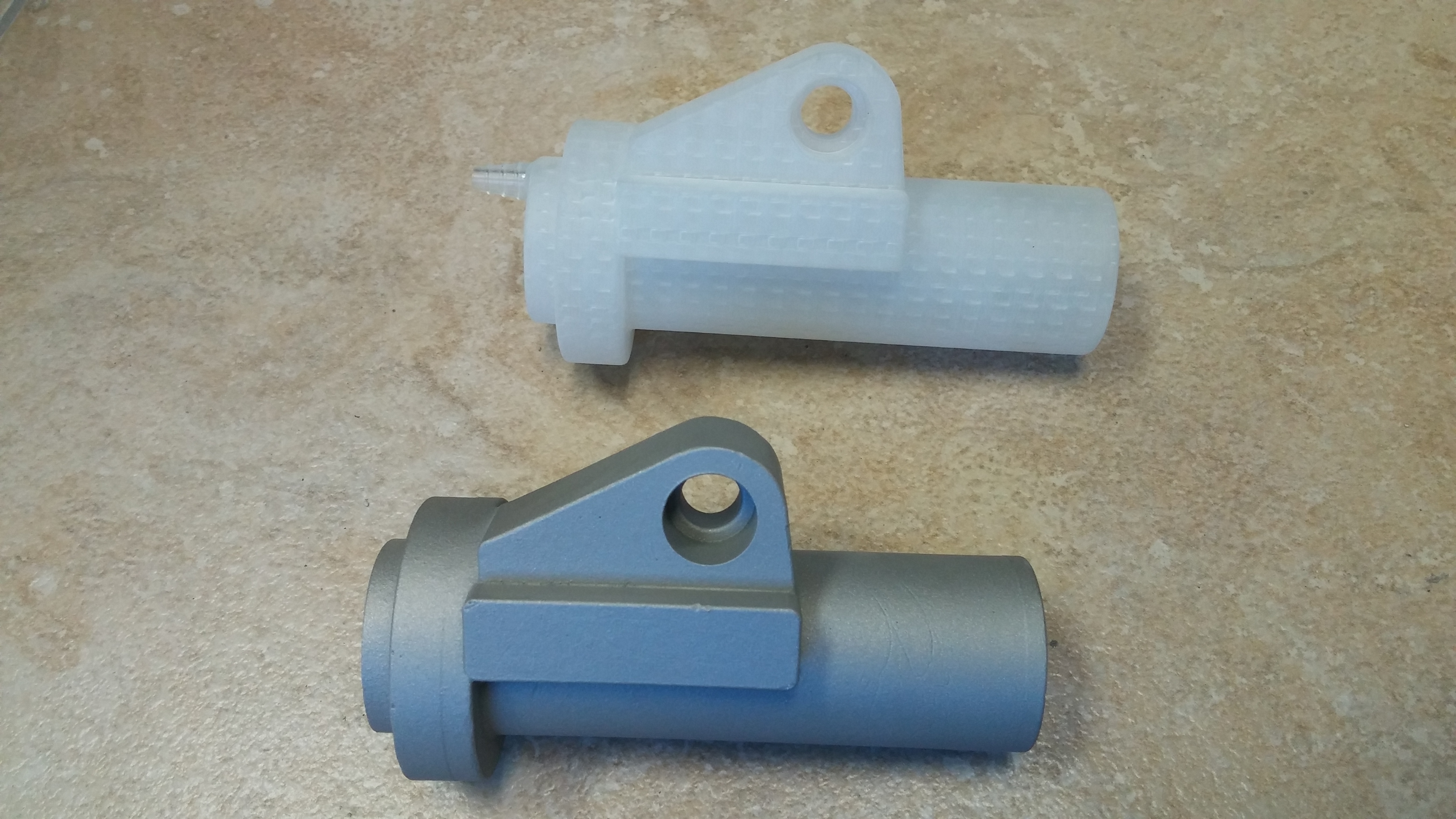

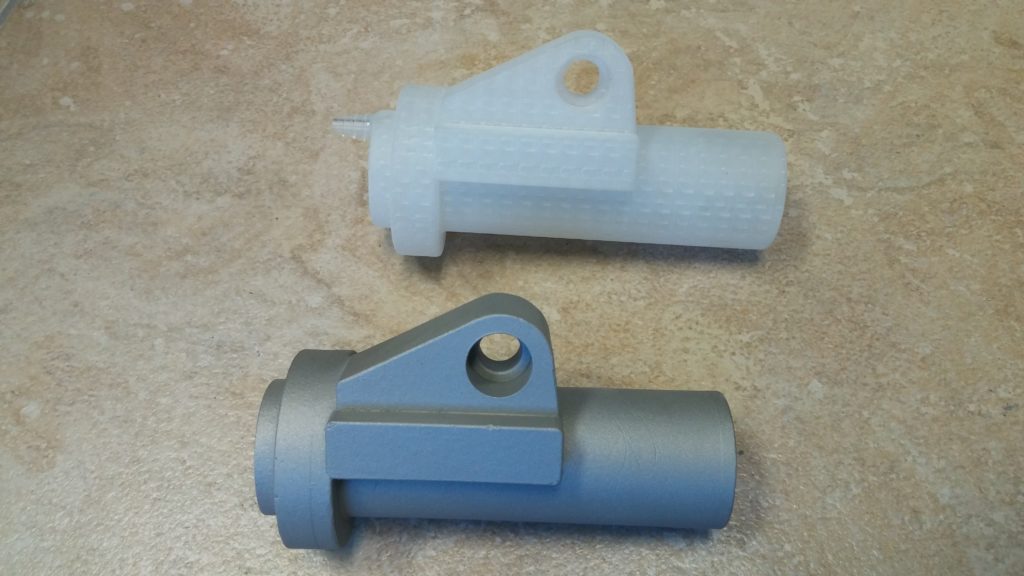

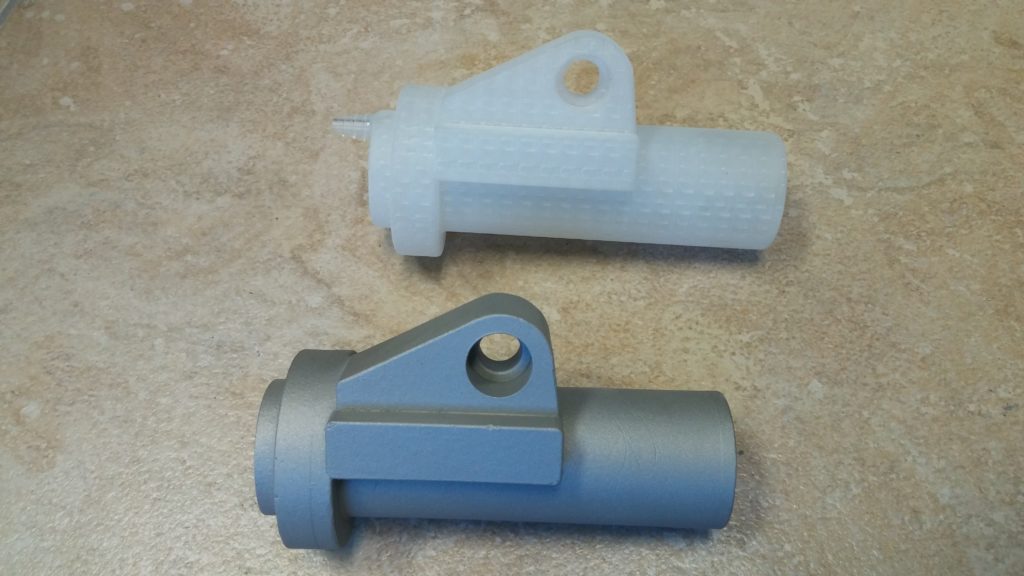

Hydraulic Housing, A60 Resin and cast 316 stainless, side by side.

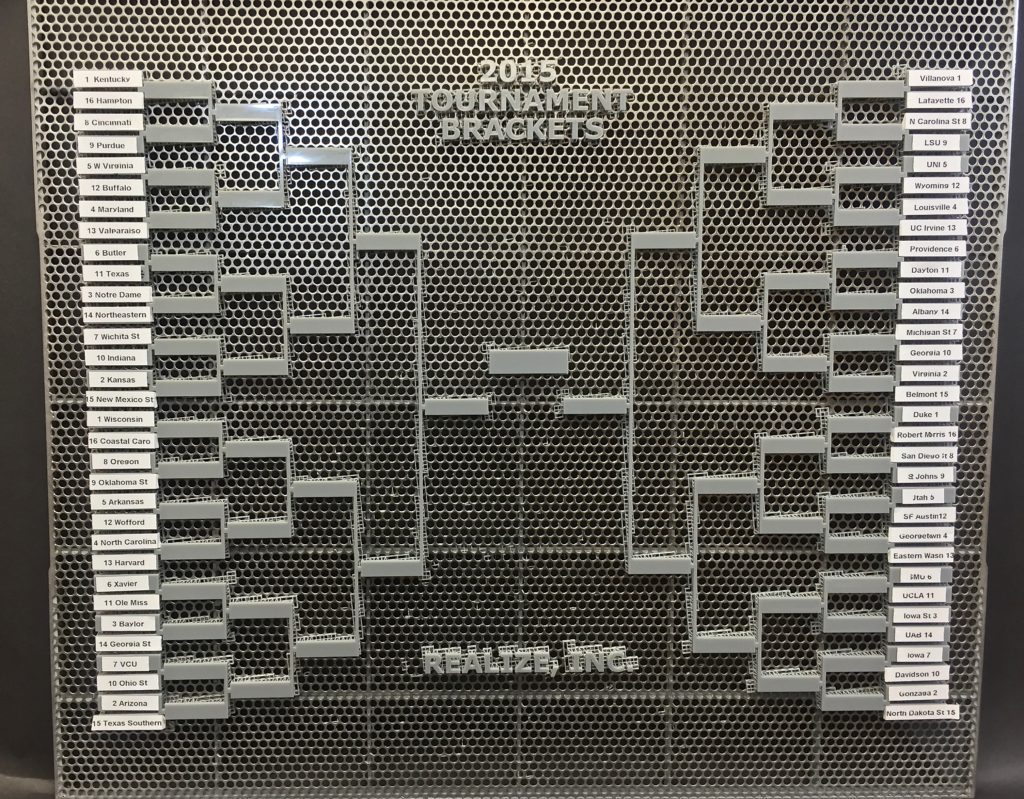

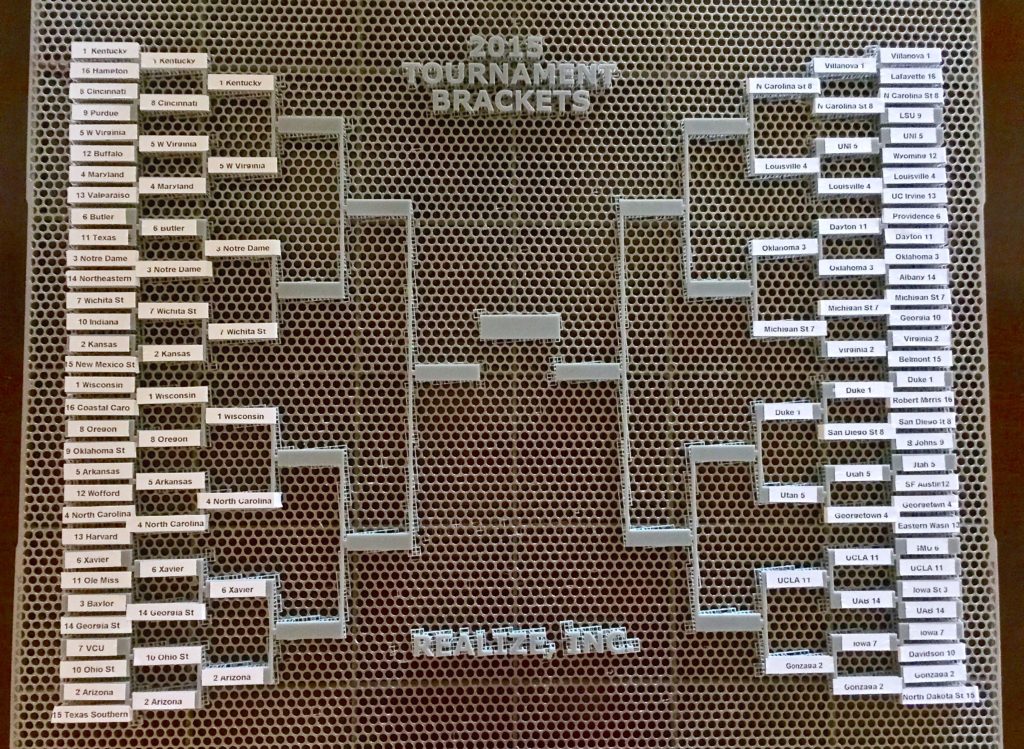

Realize CLient Profile: ICS/Girard

We help ICS and Girard Equipment by providing them with QuickCast patterns created from one of our SLA machines. This type of work is unique from a standard SLA job because in the end, the pattern will be used to make a metal part. These individual SLA patterns are used by foundries as part of a process called investment casting which will produce one metal part for every SLA pattern used. More specifically, the work we do for Girard helps them create short run metal prototypes for the tanker trailer industry and when they reach out to us we are able to supply them with fast turnaround, high- quality QuickCast patterns. We asked ICS Foundry Manager Bill Laiacono a few questions about the industry and how they use additive manufacturing for their business.

Tell us about your business.

ICS is a captive foundry, supplying stainless steel investment castings to Girard Equipment, Inc., manufacturer of vents and valves for the bulk liquid transport industry.

How do you use 3D Printing/Additive Manufacturing/QuickCast to help with your projects?

Mainly prototyping. With the help of Realize, Inc., we can take a part from idea to cast and machined stainless steel in less than a week.

What is your overall feedback about our services and are there any examples of how Realize has helped your business?

Every interaction with Realize, Inc. has been a positive one. Realize has always been responsive, quick to produce and very reasonably priced. Customer service is pleasant and accommodating too.

How can Realize can help your business in the future?

By simply providing the same quality, value and responsiveness we have come to expect from Realize.

Why do you think there is such a growing buzz about the 3D Printing/Additive Manufacturing industry?

The diversity and range of 3D printing has grown immensely. Because of 3D printing, items can now be realized in a matter of hours that used to take weeks. The results are almost instant.

What is something that you personally would like to have 3D Printed?

A custom wall mounted bottle opener. I appreciate the simple function of a unique bottle opener.

3D Printing/Rapid Prototyping/Additive MFG

3D Printing/Rapid Prototyping/Additive MFG