Now offering at Realize: Somos® EvoLVe Resin !

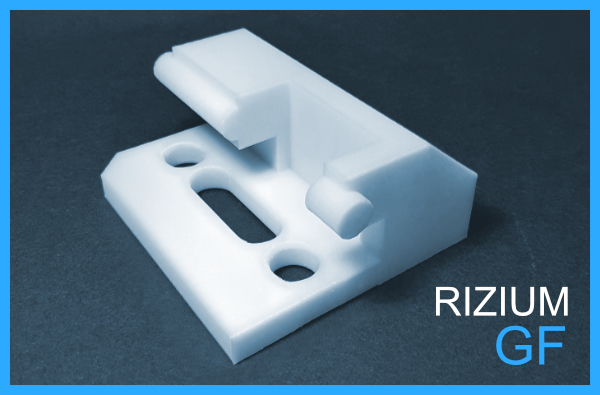

We are excited to announce we’ve added Somos EvoLVe 128 to our material portfolio. This ABS-like resin produces highly accurate and durable parts for prototype and functional testing. These exceptional properties make it ideal for applications such as automotive, medical, electronics and more. Feel free to try out Somos® EvoLVe 128 on your next project! Request a free part or sample.

Key benefits & features:

- Tough prototypes

- Easy to finish

- High detail

A Satisfied Realize Customer Testimony…

I just wanted to let you know that the engineers in my group are really excited about the new Evolve material. The Evolve material aesthetically looks fantastic and “has the appearance that it came off of an injection mold tool”. The prototype samples that you have built for us seem to be consistent on dimensional accuracy and we have even been successful with using these samples in early cycle testing, which is a testament to the strength of Evolve. You definitely have a winner with this material.

Prototype Services Manager, Safety Equipment Supplier

Do you have a project in mind? Please use our custom quote form below.

Parts Requirements Upload

You are almost finished! After your files have uploaded and you see the “success” icon, please be sure to fill out our form below. Enter your name, the time of your upload and your email address. Then press the "upload" button. You will receive a confirmation email.

3D Printing/Rapid Prototyping & Manufacturing

3D Printing/Rapid Prototyping & Manufacturing