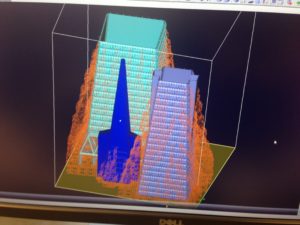

Realize recently created a scaled model version prototype of the Transamerica Pyramid.

We worked with designer, Adam Voorhees, who builds architectural models. He needed a prototype of the skyscraper at a scaled height of 53 inches to go into a museum exhibit. There was time spent upfront with Adam talking over the project with Brian Cazzell from Realize about file issues and other build options.

Adam was knowledgeable about our processes and what it was going to take to be able to build this. We were only concerned about the external parts of the building. It was a good clean file from the beginning and then we cut it into three sections and inserted a dowel pin system. We used Acura 60 and one of our SLA 5000 machines to create the parts.

The entire process took about 4 days- the build time for this project was approximately 84 hours.

We talked with the client to find out more about his experience and how this prototype will be used:

“The parts have been received, they look great. Everything with Realize went well – cost was on target, build time was quick, packaging was excellent, and Brian was extremely helpful. This model is going to be used for an exhibit on the architect, William Pereira” – ADAM VOORHEES

3D Printing/Rapid Prototyping & Manufacturing

3D Printing/Rapid Prototyping & Manufacturing