At Realize we get very excited when an interesting project comes through our doors. One recent prototype we worked on is for a new product that is looking to revolutionalize the concept of locking your bike! We talked with the creator and founder of Linka Mohamed Mohamed.

Realize: Tell us about your product.

Mohamed: As I’m an avid everyday cyclist, I realized I needed more security and peace of mind for my bike and regardless of how bulky and expensive other locks were, I needed something that told me if something was wrong so I can address it immediately. If you wait a few hours, it’s too late. The recovery rate for bikes in the U.S. is less than 2%. After some research and asking many people from various environments, everyone seemed to have the same concerns. So LINKA was born! LINKA mounts to your bike in 5 minutes and stays there so you’re always ready to lock up. With a built-in siren and an accelerometer, LINKA can tell when your bike is in danger and will notify your smart phone. Beyond that, LINKA will auto-unlock as you approach making it quicker and easier than ever to ride away.

How did you use Realize and 3D Printing to help with your project?

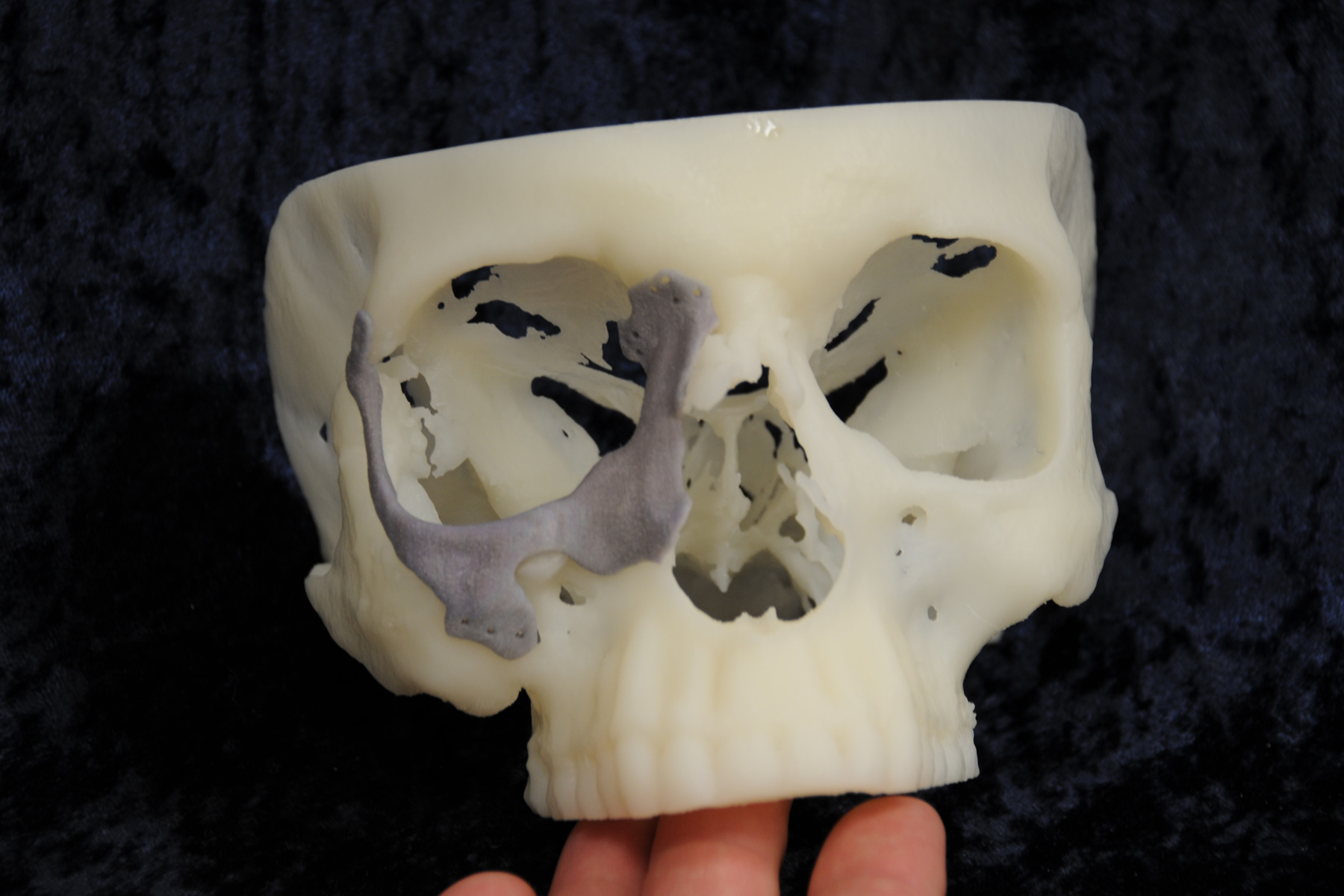

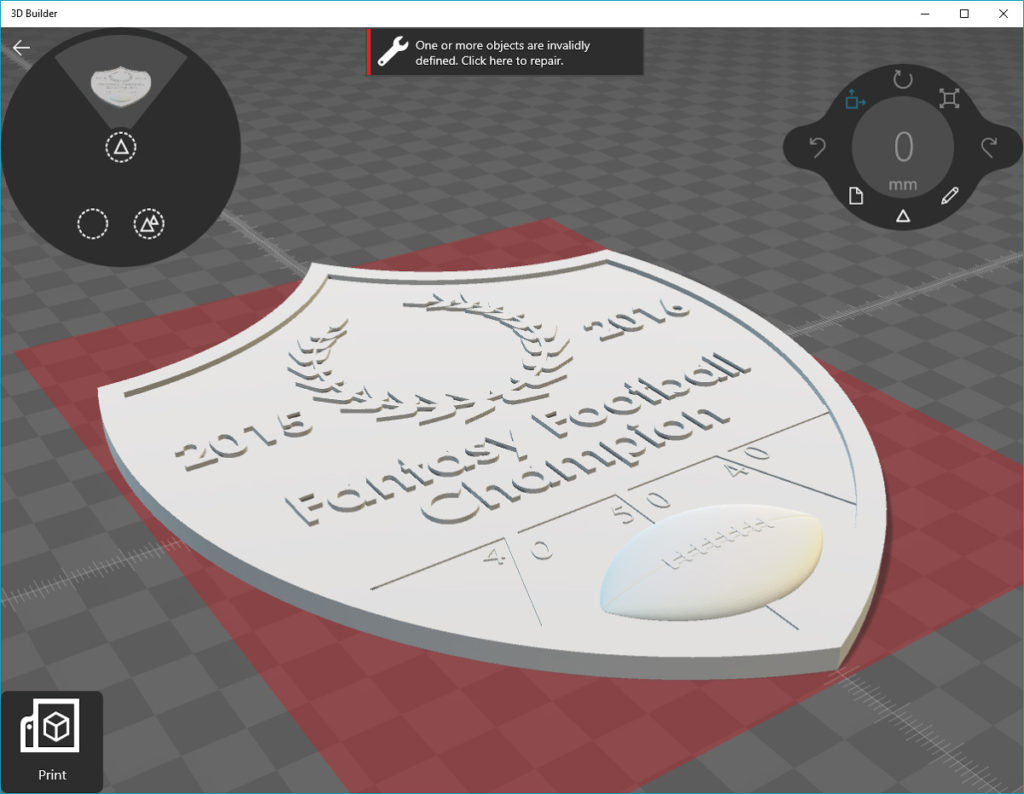

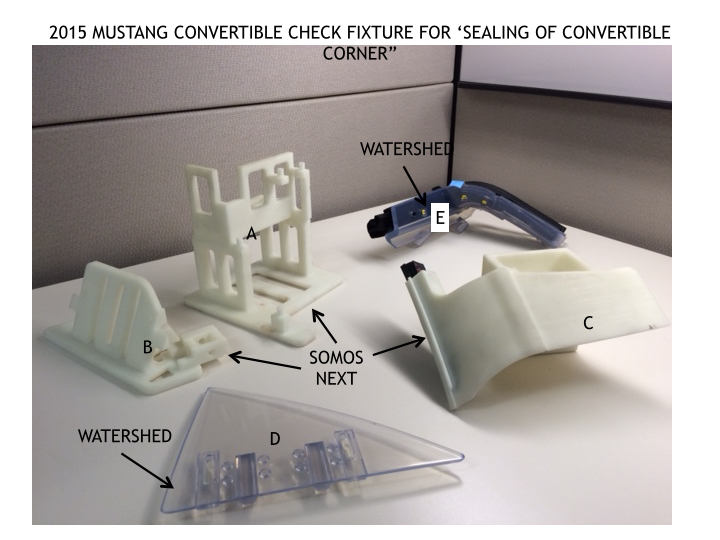

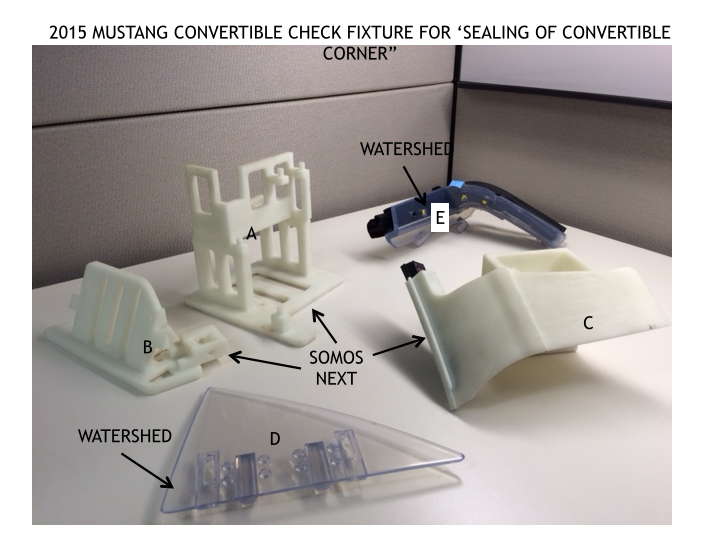

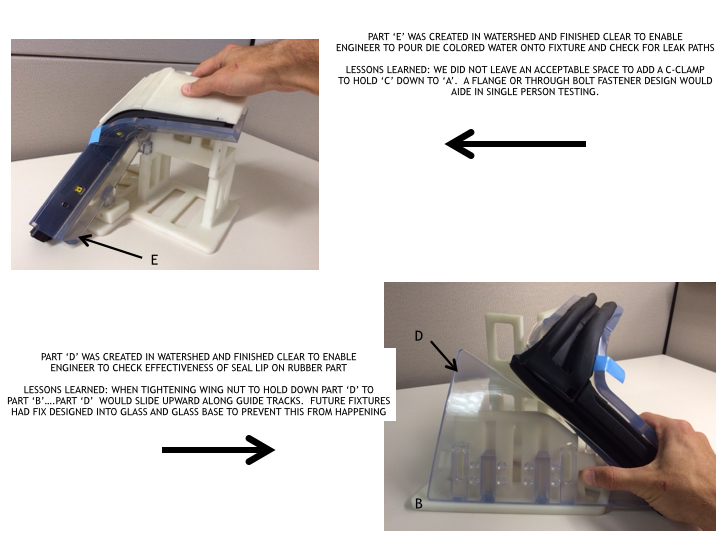

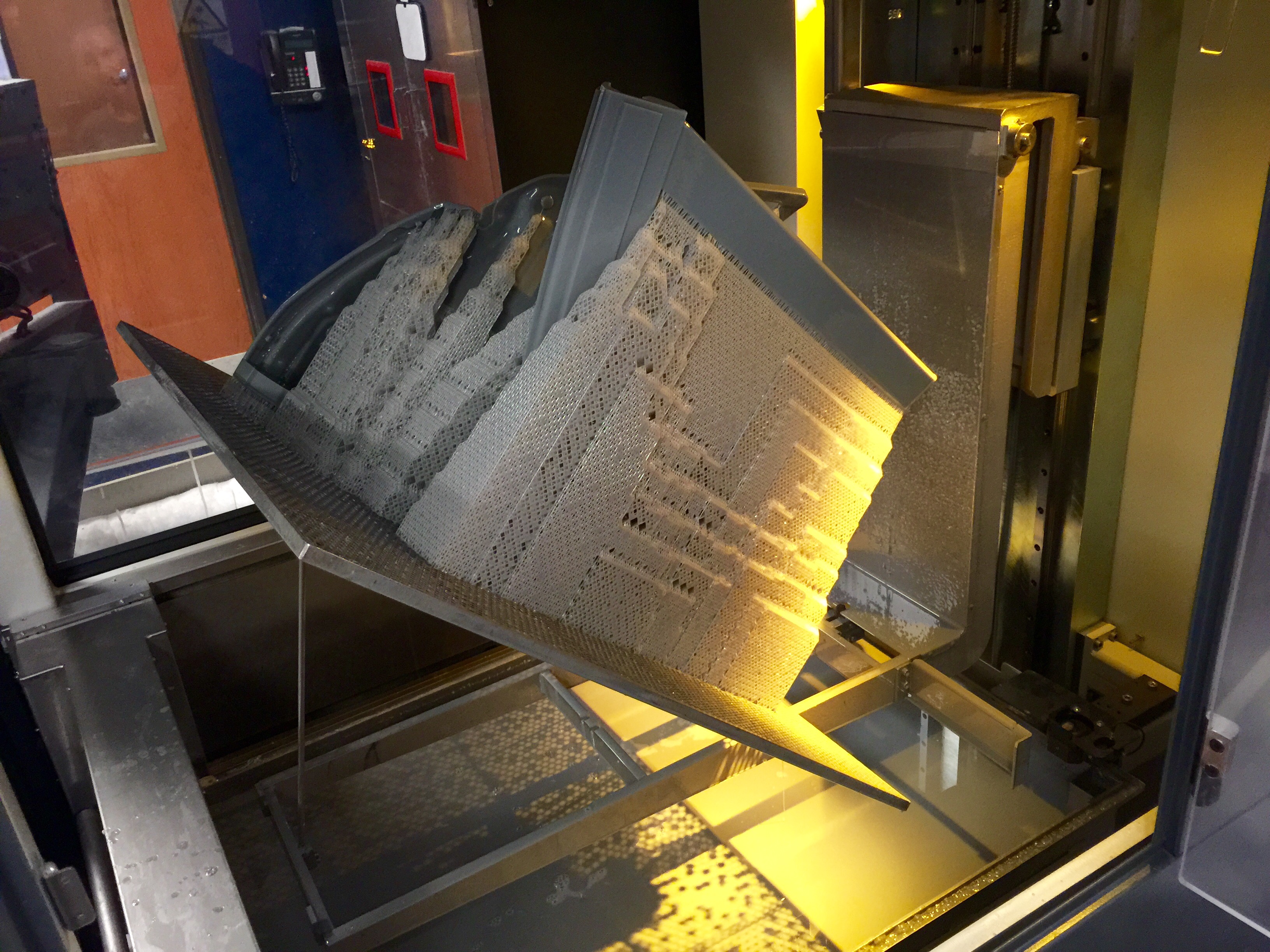

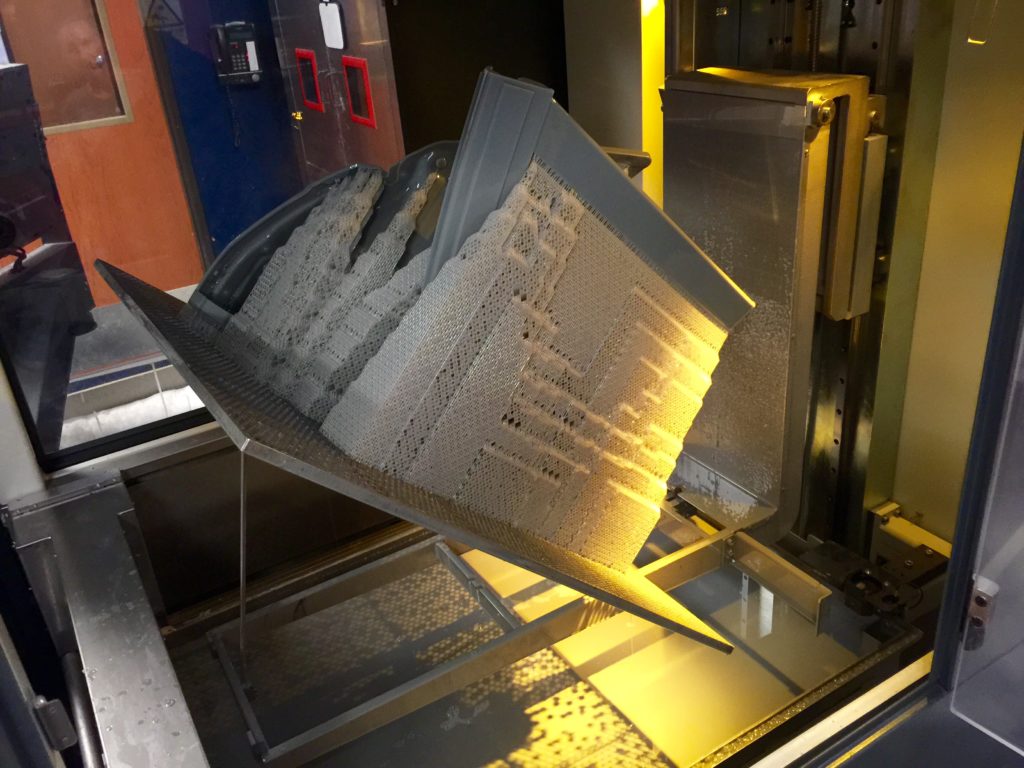

We utilized Realize’s ability to get us finished looking SLA parts to help us with a fit and finish of our end production product. We also utilized the RTV mold process to make rubber gaskets in various colors. This really allowed us to have high quality photos for our shoots.

How do you think you will use additive manufacturing in the future and are there any new directions or capabilities you would like to see in the industry?

I wish there was a way to find quick turn solutions to simulate machined parts in aluminum and steel. Local shops have long lead times and the cost is quite high. We will continue to utilize existing additive manufacturing tools to get really quick relatively inexpensive prototypes made.

What were the biggest challenges with creating the Bike lock?

Biggest challenge for us is multi-faceted. Balancing bluetooth range combined with designing something with low-power consumption. From a mechanical side, tolerances need to be really well captured as a non-functioning bike lock provides more issues than say a non-functional bike light.

With such a cool product coming out is there a follow up idea you have ready to go?

We currently have many products in our roadmap and can’t wait to introduce them all once the time is right!

LINKA is currently available on pre-order for $99 with an expected ship date of January 2016. Find our more through our Kickstarter campaign here

3D Printing/Rapid Prototyping/Additive MFG

3D Printing/Rapid Prototyping/Additive MFG