What do you do at Realize?

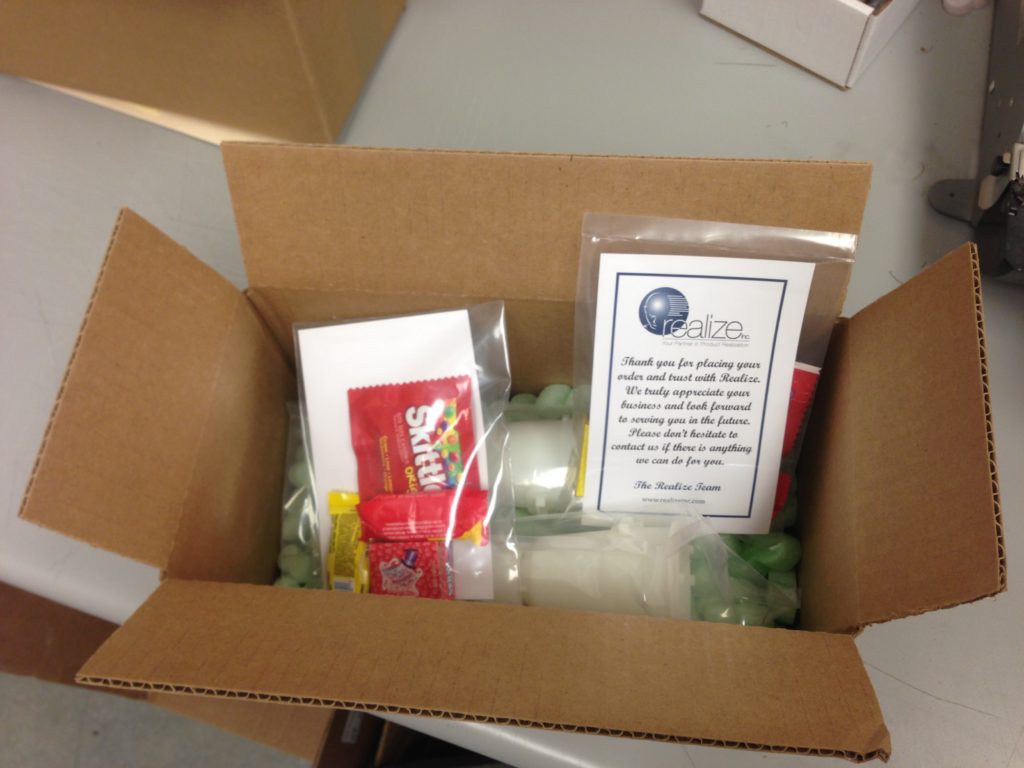

I’m a quality control specialist and take care of all the shipping. I drive the Realize Honda Fit around town making deliveries.

What challenges do you face during a typical week at Realize?

Trying to make sure things are out on time. Some days I’m at the mercy of when parts are finished and trying to meet the delivery schedules.

Most difficult thing ship?

Shipping all of these things can be tough. Everything is so fragile, how we get them to people takes a lot of thought.

How does Realize do things differently than the competition?

I think there is an emphasis on quality. We put out the best product possible. Everyone puts their hearts into what they are doing.

What are some of your favorite things in the world?

I’m a Texan at heart……..I like to water ski. I’m a very adventurous person, outdoorsy. Anything craft related…crochet…the afghan I’m about to finish has been a 24 year old project.

Favorite meal?

My favorite item would be avocado tacos…avocados, lettuce tomatoes in a soft tortilla shell in Texas…like them best from our favorite taco shack in Portland, Texas. To drink a large sweet tea, love it. And for dessert homemade pecan pie is my favorite.

What music are you listening to right now?

I listen to mixture of country and 80’s, Bon Jovi was just jamming in the back…old school country…the Oak Ridge Boys…and George Strait.

What fascinates you most about Rapid Prototyping?

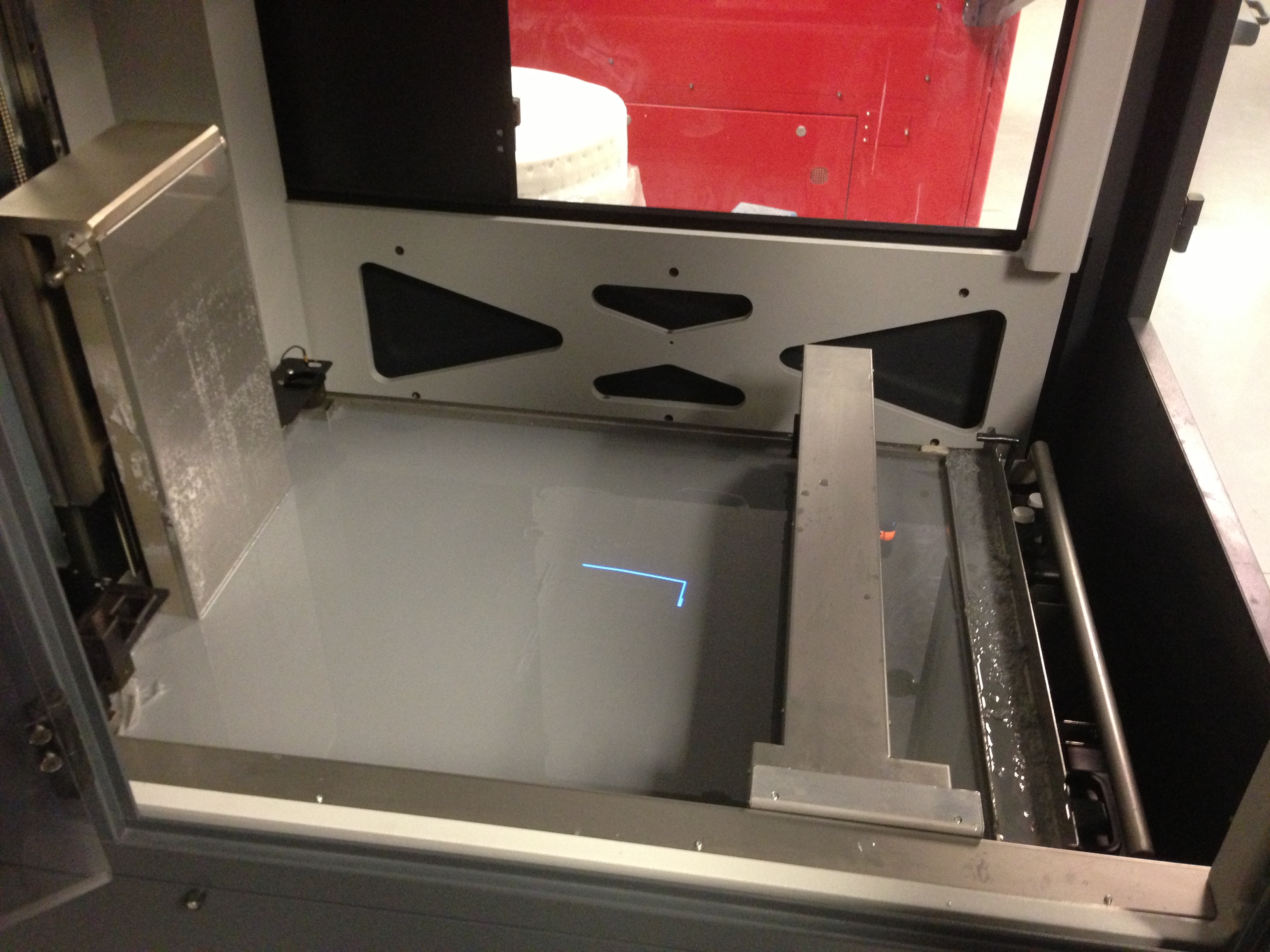

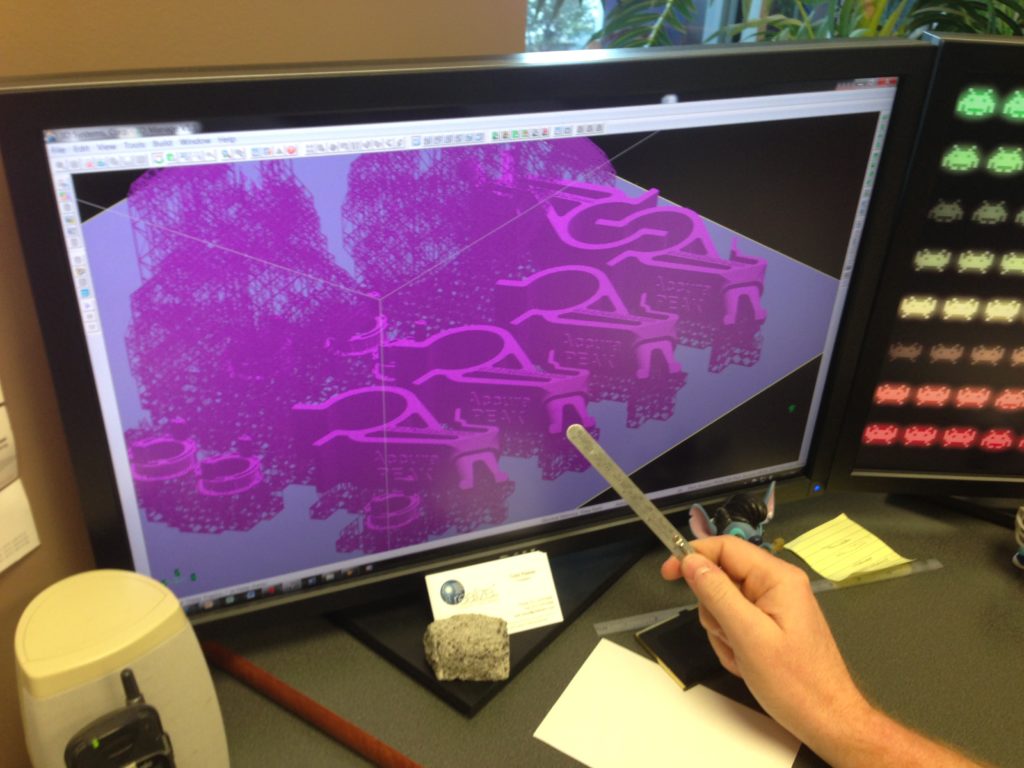

I think it’s what can be built and how much detail can go into the parts we are making these days…the process….thinking that liquid created these parts…amazing.

You can take two movies with you to space…which do you bring?

Dirty Dancing, The Cutting Edge.

Name one thing you would like to Rapid Prototype?

My cat. His name is Jasper….orange and white tabby. At Christmas time he lays under the tree….I want to always remember him like that.

3D Printing/Rapid Prototyping/Additive MFG

3D Printing/Rapid Prototyping/Additive MFG