The Realize Q&A with…Tim Caffrey, Associate Consultant, Wohlers Associates, Inc.

Tim Caffrey earned a bachelor’s degree in mechanical engineering at the University of New Mexico. Caffrey was employed by The Boeing Company for 10 years, including four years directing the operation of the company’s in-house additive-manufacturing (AM) services. Caffrey served as plant manager of Plynetics Express—which was, at the time, the world’s largest AM service provider. His 18 years of writing experience includes aircraft engine maintenance and pre-fight test procedures for Boeing, engine case repair procedures for Pratt & Whitney, technical content for the web, and advertising copywriting at Walmart’s corporate headquarters.

Caffrey has worked closely with Wohlers Associates since 2000 on this annual industry study and many other projects. Caffrey’s role at the company expanded in 2011 and has since been working on a wide range of consulting projects. He also speaks and represents Wohlers Associates at national and international events.

Realize is scanning the globe for Additive Manufacturing industry experts to share their views about where we are today and where the future will take us.

Where do you see the industry going in the next 5 years?

The industry will continue to grow in two distinctly different directions. On one end of the spectrum, we’ll see the low-cost personal 3D printers improve in performance, offer additional materials, and drop in price. We (Wohlers Associates) don’t think every home will own a 3D printer though; the more likely scenario is web-based service providers and 3D print shops analogous to today’s 2D print shops like Staples, Office Depot, and FedEx Office. On the other end of the spectrum, we’ll see industrial systems designed for specific applications, specific industries, or even specific individual parts. Speed, max part size, and the selection of materials will all increase. We’ll see hybrid systems that perform more than one operation, both additive and subtractive.

There has been a ‘new generation’ of users exposed to AM/RP/3DP over the past few years, along with a huge media buzz. How do you see this camp and the ‘old school’ camp coming together?

Initially, these two camps were indeed cut off from one another. One user went to RAPID and to user group meetings. The other user went to maker faires and community hacker meetings. Now we’re seeing overlap at new types of shows, like the “Inside 3D Printing” series. Also, we’ll begin to see new 3D printers that can be used by both camps in the $3,000 to $8,000 price range. These will be purchased by the “old school” companies and by the makers, and that’ll have a unifying effect.

Still, one could argue that these two camps should be separate. They share one thing: layered additive manufacturing. But a $1,000 open-source material extrusion system has absolutely nothing else in common with an electron beam, metal powder bed fusion system in a production environment making orthopedic implants, for example. These two users have vastly different requirements and needs from their respective user communities.

What challenges/opportunities do you feel service providers, like Realize, face today?

In some ways, nothing has changed. SPs need to find and keep customers. How? Delivering a service that is valuable to the customer, delivering something the customer can’t (or doesn’t want to) do themselves.

There’s an educational aspect. Explaining the differences in quality, materials, repeatability, etc. Also, offering A to Z service, from CAD to urethane castings and high-quality finishing. Even a knowledgeable OEM that owns a machine or two probably does not have all these capabilities in its arsenal.

What are some misconceptions about the capabilities of the technologies?

1-That it’s a pushbutton technology. As you know, there’s a lot of work, craft, art, and science required pre- and post-build.

2-That everyone will someday own and operate a 3D printer.

3-That you can make an airplane engine fuel nozzle in a $795 printer.

4-That the industry just appeared overnight.

5-That printing guns is a safety and security issue. Really, it’s just another extreme endorsement of 2nd amendment rights.

6-That 3D printing is a less-expensive form of manufacturing. It’s can be, but not necessarily.

7. That 3D printing is more energy efficient than conventional manufacturing. It can be, but not necessarily. Most analysis to date suggests just the opposite.

How do you think 3D printing can change the way we live in the future?

I like to think we’ll develop into smarter consumers and product designers, and reverse the “Walmart-ification” of retail, which I define as the selling and buying of millions of cheap junk items that break too soon. We’ll see products that are well designed and manufactured, they might be personalized, they may cost more, but they will last longer and function in a better way.

As I said, we don’t think there will be a 3D printer in every home next to the HP inkjet printer. Even people that design or co-design online will still go the the 3D print shop around the corner or click the “Print” button on the online part portal.

How would you describe AM/RP/3DP to someone who has never been exposed to it?

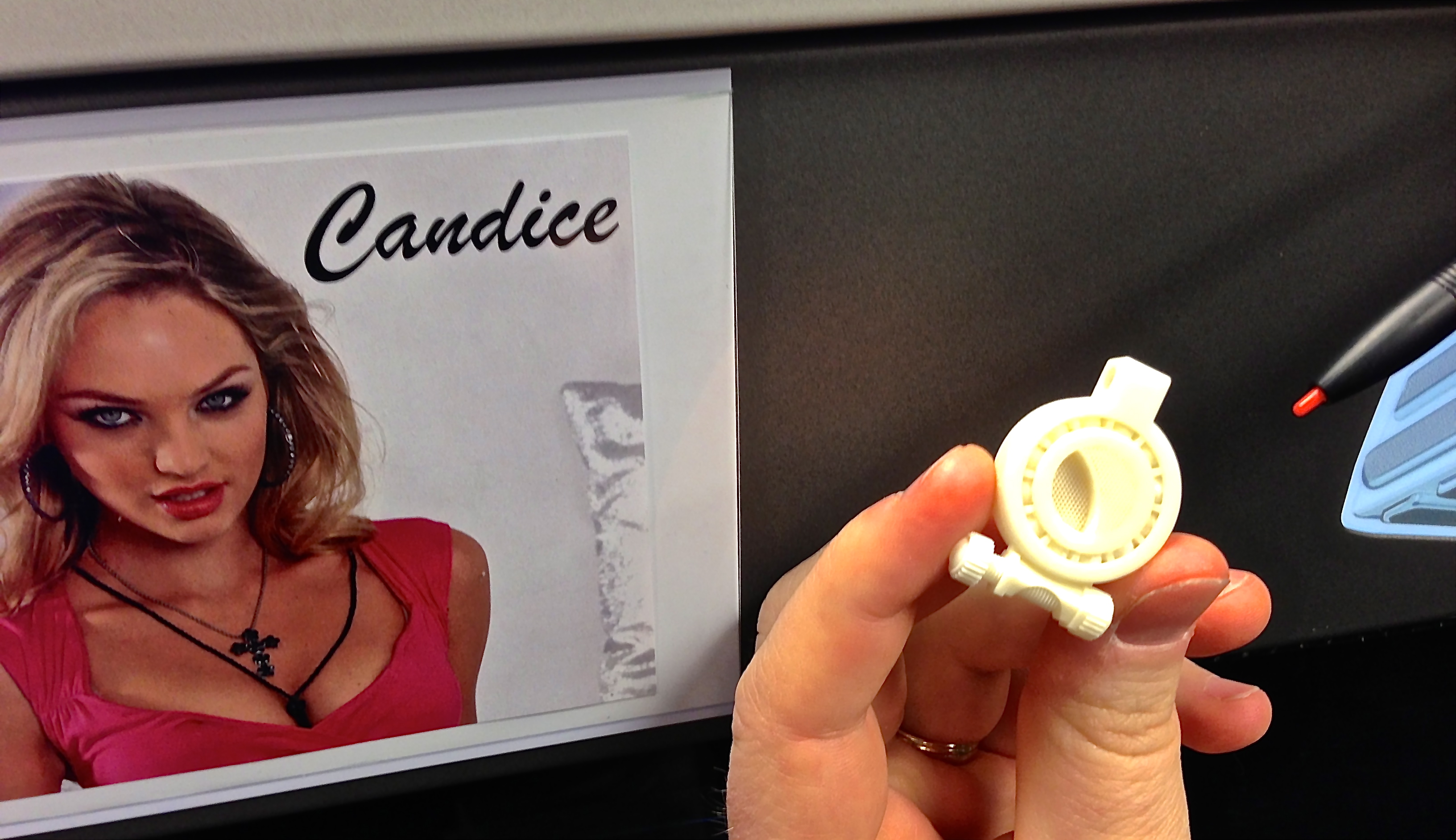

The software slices a computer file of a 3D geometry into very thin layers. The AM machine builds the 3D part by successively stacking these thin layers. Each new layer bonds to the layer before it. There are seven different ways these layers are created, from glueing sheets of paper together to using a laser to melt metal powder. The machines run unattended, but a significant amount of labor is needed for preparing the file and the machine and for cleaning and finishing the parts after the build is complete.

3D Printing/Rapid Prototyping/Additive MFG

3D Printing/Rapid Prototyping/Additive MFG