One of the more interesting and exciting projects we have been working on at Realize involves customizing and creating parts for automobiles using additive manufacturing. We talked with the Senior Designer on the project about the creation of these 3D prototypes.

How did you use Realize and 3D Printing to help with your project?

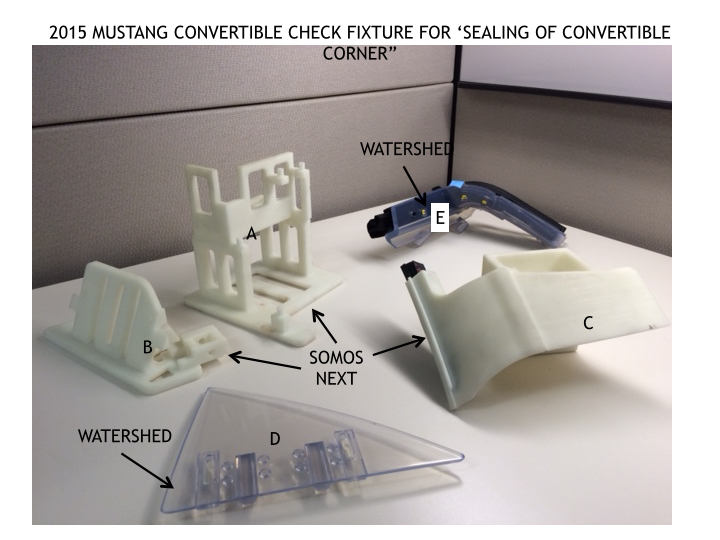

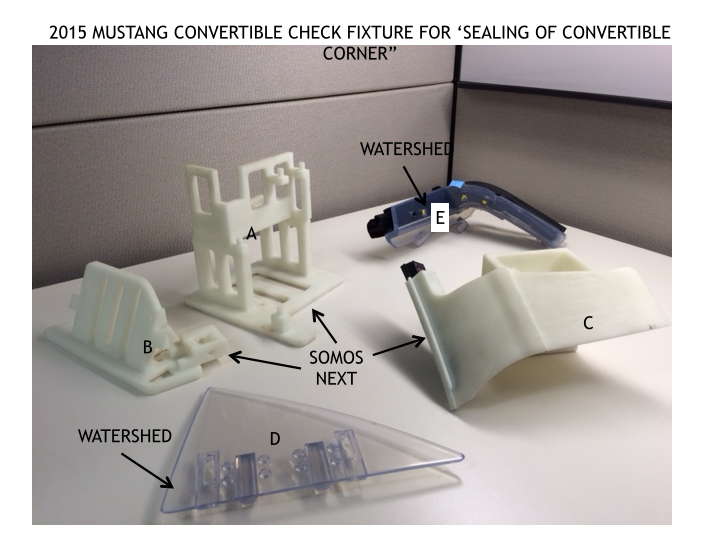

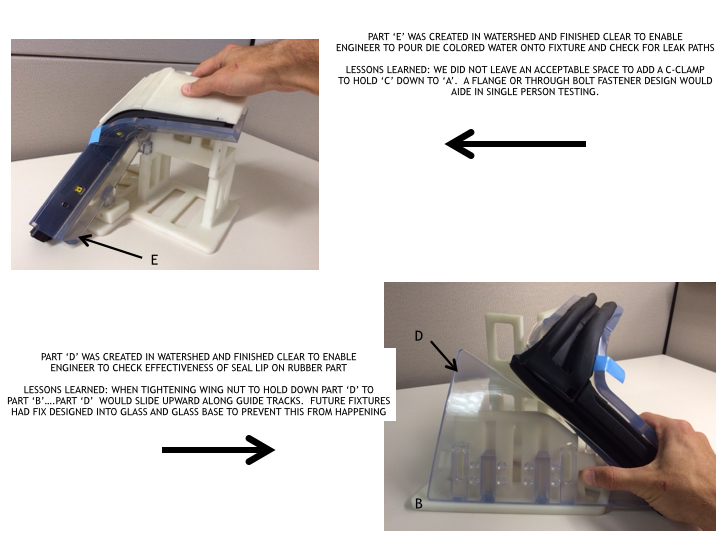

Originally our Product Design and Development teams were looking for ways to replicate automotive sheet metal and trim based on 3D Math CAD data. We wanted something we could mount our actual parts to that would show how our parts were intended to perform on the vehicle if it was built to spec. Eventually our company decided to starting using 3D Prints to replicate changes to sheet metal and trim to show customers how a certain sealing environment changes would be helpful to our methodology. This would help our customers understand why we needed to make environment changes. Then we turned to using 3D Prints to make check fixtures for our sealing environments. During prototype phases, getting actual sheet metal to mount our parts to in the environment it was intended by CAD can be difficult. Also, a vehicle would have to be located for a meeting. Being able to replicate a portions of the body side, door and trim panels and include door swing gave us the ability to bring our sealing environments straight to the customer in an office setting for discussion. I cannot stress enough the complexity of some of the fixtures and jigs we have designed.

How do you think you will use additive manufacturing in the future and are there any new directions or capabilities you would like to see in the industry?

Our Teams are always looking into how we can take additive manufacturing to the next level. We strive on continuos improvement and are always fine tuning our fixture and jig designs in CAD to get the most testing possibilities we can out of them. In the beginning we had single parts printed to mount to. Now we are making multiple piece fixtures and jigs that you can simulate glass movement, door closing and a variety of environment possibilities with shims and hardware.

What were the biggest challenges with creating the parts we did for you?

Learning the properties of the various materials. Our customers have always demanded fast turn around times and we cannot always wait for our preferred materials for printing. In some cases we have had to choose something different than our normal selection so we can have the parts in our hands by a certain date for a customer meeting. Some times it works out for us and others it does not. We try not to stray away from what we know will work, however, some times we are forced to due to timing requirements.

What is something that you personally would like to have 3D Printed?

If I still had the files it would be the CAD parts I made back when I first started learning in CAD design 17 years ago. The only way to really understand what a software is capable of is to log hours on it and explore beyond what you are taught. So I used to stay after classes and design my own ideas and concepts and also on my lunch hours. This was back when SDRC I-Deas was popular and everything was still on Unix. It was also a few jobs ago. I saved a lot of those files on a hard disc many moons ago but couldn’t tell you what happened to it.

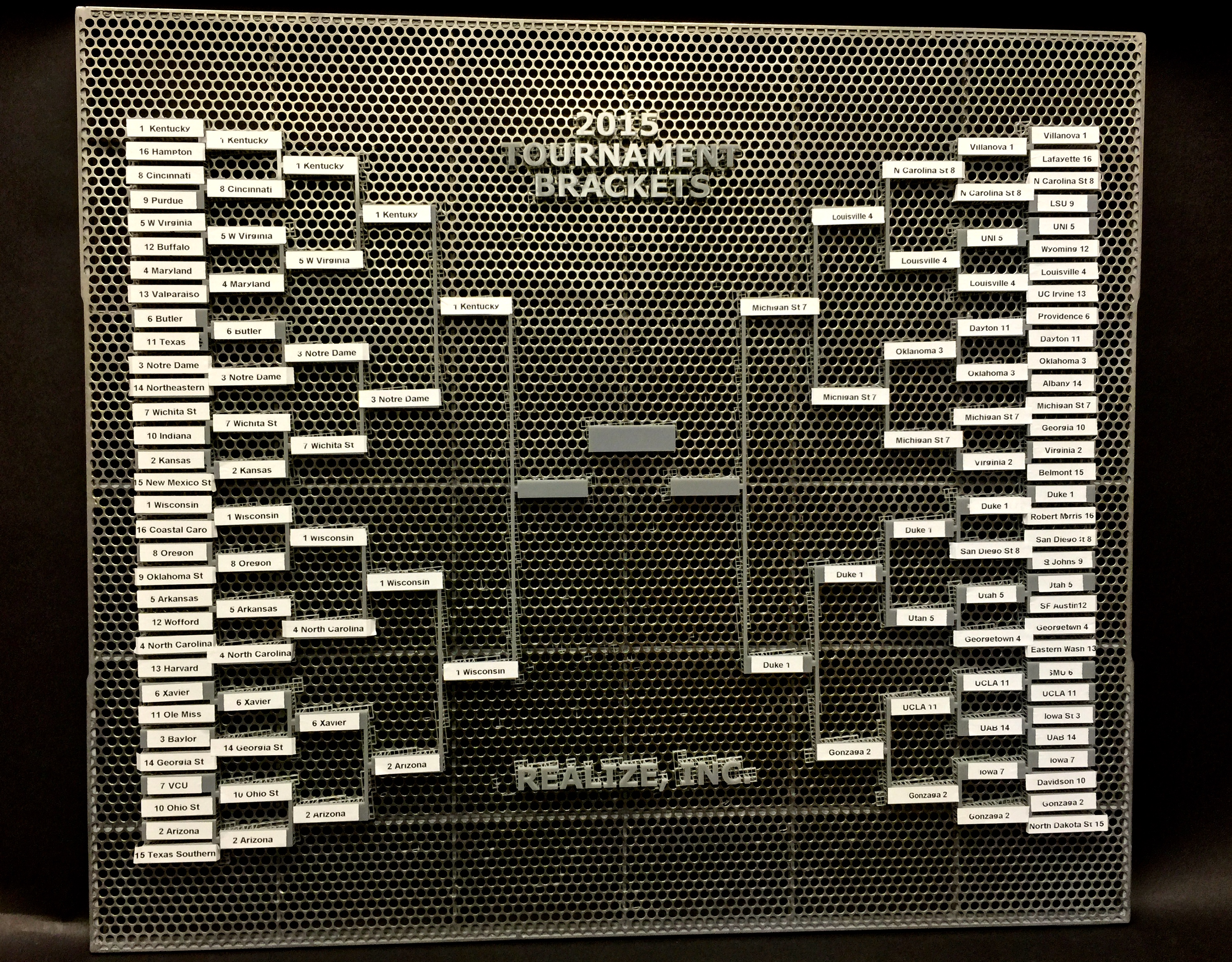

3D Printing/Rapid Prototyping & Manufacturing

3D Printing/Rapid Prototyping & Manufacturing