The Realize Featured Project: Volvo Truck 3D Model

Realize, Inc. worked with Auto Research Center to create a 3D Printed model of a Volvo truck.

“When Steve (ARC) came to us for help we were very happy to be a part of it. This SLA project is especially unique because it is going to be on display in our customers lobby. These are fun projects for the whole team and when it all comes together like this- it is always exciting to see the finished model.”

-Alan Conlu, Sales Manager at Realize, Inc.

We asked ARC’s Engineering Manager, Steve Roskowski, a few questions about the project.

Realize: How did this project come about?

Steve: The Volvo truck model came about to fill a void in our OEM tractor inventory. We do quite a bit of testing for both aftermarket aero device manufacturers, fleets and regulatory agencies. Several had requested the 670 VNL for their testing, so we completed it to satisfy customer requests.

What do you plan to do with this prototype?

The model is now available for any customer to use to advance their knowledge of tractor trailer aerodynamics.

What makes this design different then what’s out there now?

So far as we know, this is the only publicly available wind tunnel model of the Volvo 670 VNL for rent.

Tell us about the design process and how much time is involved for a project like this.

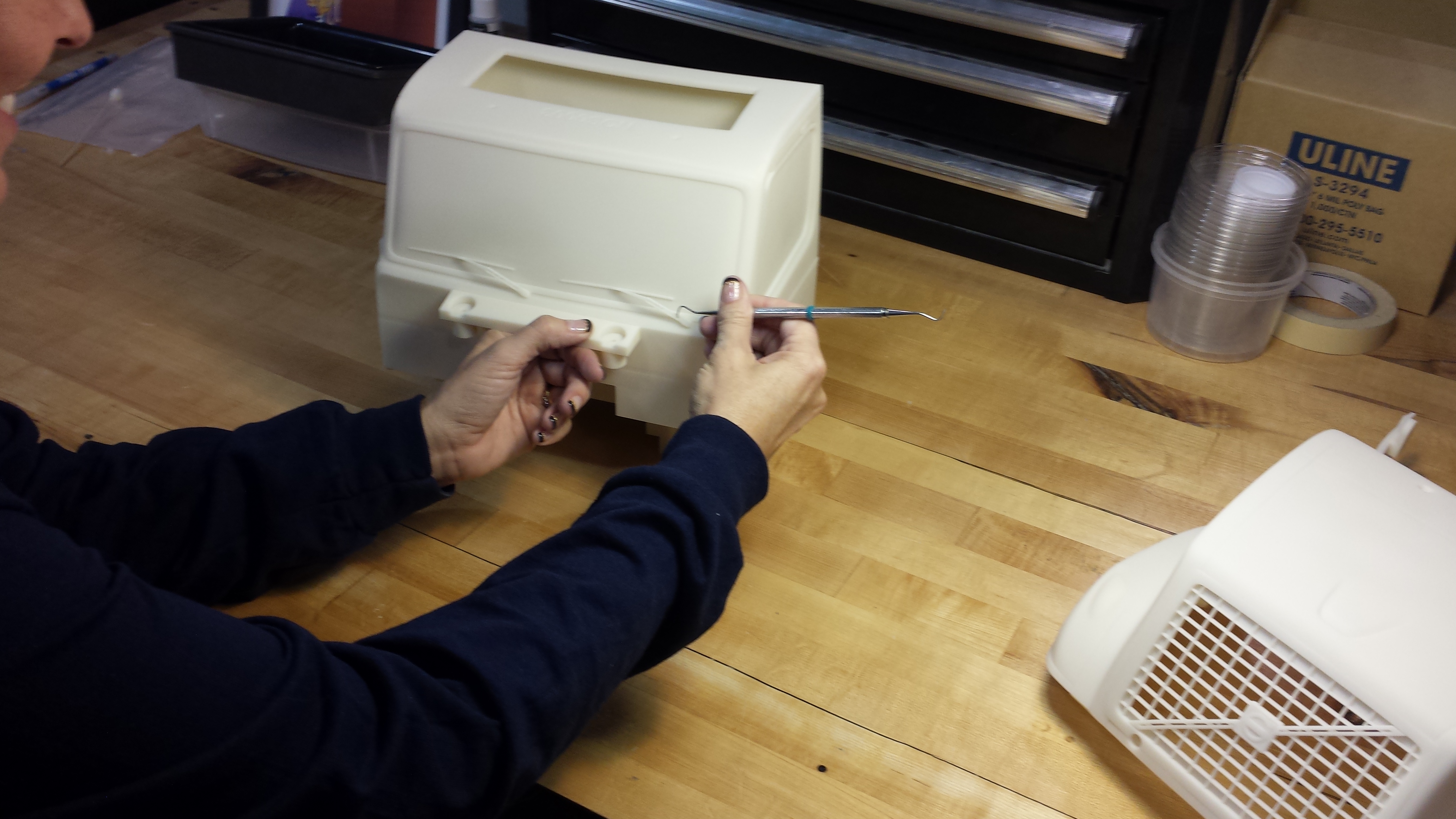

We started the design by renting a full sized truck, bringing to ARC and laser scanning it. From there it was converted to surface files and the model designed from there. The overall design process took about two months. Before we release the files to you, we have the whole model built in the CAD world to check for interferences and fits.

The hardest part in the process of creating this prototype 3D model was?

The most difficult part is scanning such a large object. The physical size simply creates unique problems that we need to work around. Since we have scanned many other vehicles for the same purpose we have a good handle on it and can get to the solution fairly quickly.

3D Printing/Rapid Prototyping/Additive MFG

3D Printing/Rapid Prototyping/Additive MFG