Realize, Inc. partners with Calsonic Kansei to create new parts for vintage vehicles.

Realize has been helping a company to fulfill the needs of a client in looking for replacement parts of vintage instruments in older vehicles. This required team work between the two organizations to come up with the right solutions to get the needed results from the parts. Our team used our collective knowledge about SLA and 3D Printing to find the right answers and provide the right look and feel to make their customers satisfied.

Alan Conlu, Sales Manager at Realize, was thrilled to be working on this project with Calsonic Kansei.

“We were excited about the challenge Calsonic Kansei presented us with this unique project. Upon hearing about their intended use as OEM(original equipment manufacturer) parts and after some initial test runs, we were glad to hear that painted SLAs were going to work as suitable replacements parts. Over the years, we’ve worked closely with their team to perfect our process in order to match the quality and look of the original parts. They have been a valued client ever since and we hope to continue to work with them in any way we can.”

We talked with Geoff Lackey, Sr. Manager Purchasing Department at CKNA about the experience working with Realize.

“Providing service parts for OEM’s is somewhat difficult at times, because there are several issues to contend with; tooling that is no longer available or has no life left. Finding alternate or new suppliers and tooling is equally difficult due to lack of interest from potential suppliers for low-volume parts, as well as internal funding issues for new tooling. However, our customers prefer to hear what we can do, not what we cannot do. So we reached out to Realize, Inc., not knowing whether the type of service they provide could solve our issues. But we ordered some samples, trialed them, received customer approval, and have not only shipped replacement parts to customers who were waiting on their vehicles to be repaired, but are now using SLA parts from Realize, Inc. to fulfill these ongoing service orders. Specifically, we manufacture instrument clusters for a major Japanese OEM, and Realize, Inc. has helped us maintain our on-time delivery rating with this customer. We appreciate the solution they provide!”

For Realize these are the types of stories we like to share. Just a small example of what makes our job so exciting and fulfilling. Working together with a client to make what was difficult and challenging a reality. Advancing excellence!

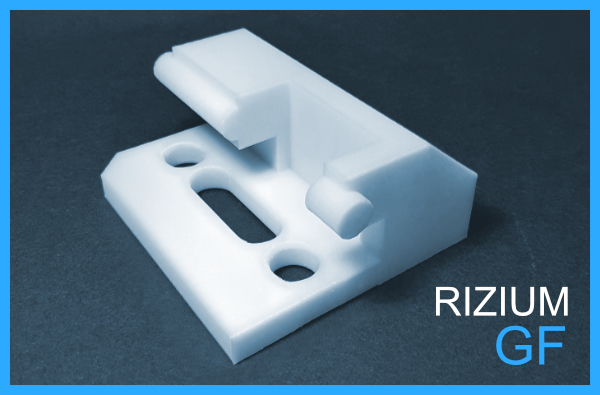

Rizium Carbon is a new thermoplastic that is reinforced with carbon fiber. It’s unique carbon composite properties are ideal for high stiffness and strength applications. Additionally, it has the look and feel suitable for prototype and end use parts. If you have concerns making parts strong enough to handle heavy loads and wear, see how Rizium Carbon can help on your next project!

Rizium Carbon is a new thermoplastic that is reinforced with carbon fiber. It’s unique carbon composite properties are ideal for high stiffness and strength applications. Additionally, it has the look and feel suitable for prototype and end use parts. If you have concerns making parts strong enough to handle heavy loads and wear, see how Rizium Carbon can help on your next project! Somos® Watershed Black a new ABS-like resin that produces extremely accurate and durable parts for prototype and functional testing. This new SLA material is based off Somos® Watershed XC 11122 and offers similar high performance and qualities in a truer black color than other SL resins on the market. Come try it out on your next prototyping project!

Somos® Watershed Black a new ABS-like resin that produces extremely accurate and durable parts for prototype and functional testing. This new SLA material is based off Somos® Watershed XC 11122 and offers similar high performance and qualities in a truer black color than other SL resins on the market. Come try it out on your next prototyping project! 3D Printing/Rapid Prototyping & Manufacturing

3D Printing/Rapid Prototyping & Manufacturing